global@hmeonline.com

Mon to Fri 09:00 – 17:30

Performance characteristics

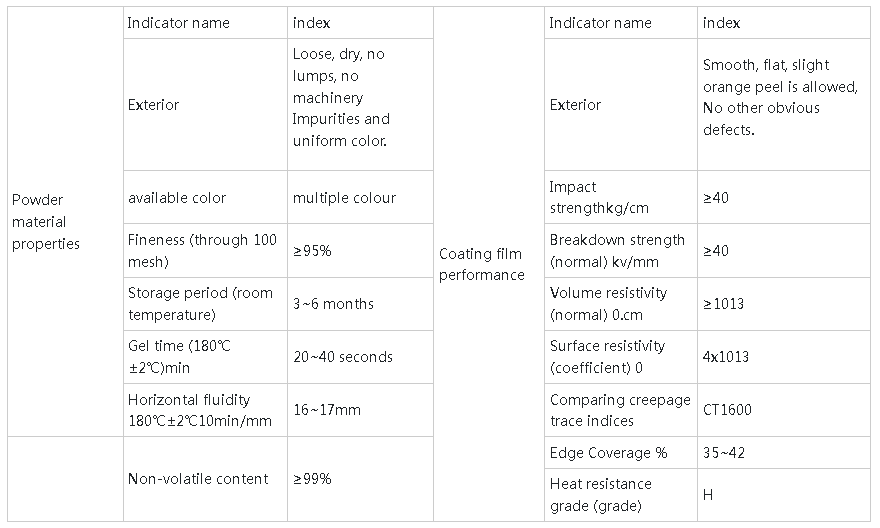

Our company selects high-purity solid epoxy resin and special composite curing agent based on the actual situation in our country, which is made through processes such as hot mixing, crushing, magnetic separation, etc. Compared with ordinary insulation powder, it has better heat resistance and thermal shock resistance, and the coating is smooth, high-density, and has good electrical strength.

Purpose

Insulation coating for rotors, iron core slots, and iron core ends of DC motors and motors with temperature resistance requirements.

Recommended coating process

Electrostatic fluidized bed method/thermal spraying method/immersion coating method

Product Certification

Complies with EU RoHS environmental directive requirements and UL certification.

Packaging/Storage

Packaged in high-quality paper drums (boxes), with a storage period of 3-6 months at room temperature, dry, and ventilated conditions.

Specification