global@hmeonline.com

Mon to Fri 09:00 – 17:30

It is suitable for component factories whose main business is 182 components and 210components are auxiliary businesses.

Low cost & low scrap rates.

Eco-friendly &physical advantages.

Long storage time & high yield rates.

Good ductility & durabiliy.

No hazards & no odor.

Low temperature resistant & high temperature resistant.

OEM & ODM service.

MOQ: 1

Specification

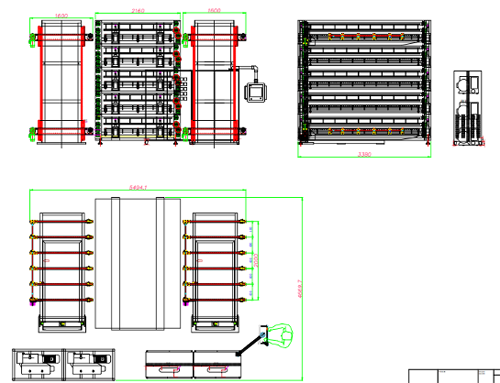

| Model | LAM1728 type single-cavity single-sheet five-layer electric heating pipe laminator |

| Technical Specifications | The effective lamination area is 1500*2600mm. |

| Power / Machine Capacity | 3x380V AC, 50HZ, total power <288KW, of which the heating power is 250KW. Operating power: 50-75KW. |

| Production Capacity | About 600-700 modules (182 / 210 modules) are produced per day. |

| Electrical Control System | Siemens PLC/AB, other configurations are Schneider brand or Chint. |

| Heating Plate Temperature Control | The heating tube is buried in the heating plate, and there is no heat conduction oil tank, which is safe and reliable, with high thermal efficiency and stable operation. Quiet and no significant heat dissipation around the laminator. It saves 25% energy consumption compared with the thermal oil laminator. Dynamic temperature uniformity: ≤± 2℃. Operating temperature: up to 220°C. Heating rate: It takes about 40 minutes to heat from room temperature to 150 ℃. Temperature control: 18 independent PID control areas with temperature measuring thermal resistance. Among them, 12 are main heating areas and 6 are auxiliary heating areas. |

| Outlet Cooling System | Cooling axial fan |

| Vacuum System | Tongda 70L/S vacuum pump |

Production