global@hmeonline.com

Mon to Fri 09:00 – 17:30

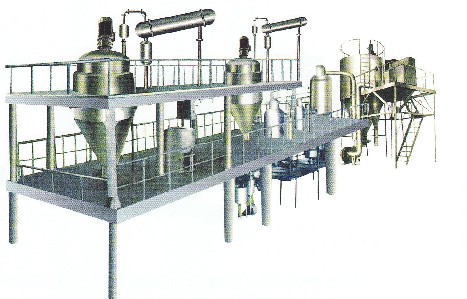

Extraction device

▲Dynamic extraction process is adopted by hot water soaking, and the extraction tank is heated by steam jacket, with a special stirring device. The crude drug is dynamically extracted at 95°C±5°C after being crushed, and the extraction rate is much higher than the original static extraction method, which saves raw materials, shortens the extraction time and saves energy.

Solid-liquid separation device:

▲A four-stage separation process is adopted, and the separation of the liquid medicine and suspended solids is completed by an automatic residue filter machine, an overflow-type bottom unloading centrifuge, a vibrating screen and a tubular high-speed centrifuge. The separation device has relatively dry medicine residue and residual medicine liquid The amount is much less than domestic ones, which reduces the loss of liquid medicine and has incomparable good conditions, avoiding coking, wall sticking, clogging and other problems in evaporation concentration and spray drying operations.

Three-effect energy-saving concentration device:

▲The selection of this equipment not only considers the nature of the feed liquid and the processing capacity of the equipment, but also fully considers the temperature coefficient, concentration ratio, constant concentration of the concentrate, simple structure, convenient loading and unloading, cleaning and maintenance. The vertical tube type is adopted, and the three-effect energy-saving concentrator is reasonably installed. The material fed into the first effect passes through the second effect and the third effect to form a paste, and the liquid medicine is continuously and automatically circulated. Compared with the three-effect and single-effect, the energy saving is more than 68%.

Spray drying device

Using a new type of high-efficiency high-speed centrifugal dryer, the operation is simple, stable, easy, automatic control is realized, the drying time is short, the power consumption is much smaller than that of pneumatic, the product has uniform particle size, good solubility and quality, and is suitable for the production of traditional Chinese medicine granules and oral liquid. The reduction of excipients and the reduction of drug doses have created the best and most ideal conditions. In terms of granulation, it can be divided into two parts: (1) a one-step granulator for spray drying; (2) a dry powder granulator for spray drying. The oral liquid production line does not need to be equipped with a drying device.

Product