global@hmeonline.com

Mon to Fri 09:00 – 17:30

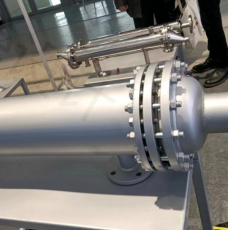

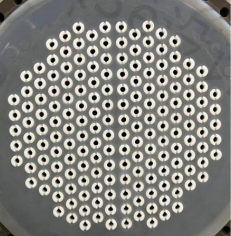

Silicon carbide (Sic) is an advanced ceramic material with high hardness,high thermal conductivity and excellent chemicastability, in fact, it is a new tvpe of heat exchanger, mainly using silicon carbide ceramic material as heat transfer mediumBecause the silicon carbide ceramics here have excellent characteristics such as corrosion resistance, high temperatureresistance, high thermal conductivity, high hardness, wear-resistant, etc, silicon carbide ceramic heat exchanger is especiallysuitable for high temperatures, hieh pressure, strone acid and alkali corrosion, hieh-speed airlow scourine, particles abrasionand other harsh working conditions, lts excellent heat exchange efficiency can meet the urgent needs of energy saving andenvironmental protection, Silicon carbide heat exchanger is a non-metallic heat exchanger, ithas a wide range of applicationsUsually mainly used in metallurgy, medicine, chemical industry and other industries. its working principle is to have hightemperature resistance and thermal shock resistance pertormance, trom l00o 'c alr-cooled to room temperature, repeatedmore than 50 times without cracks; thermal conductivity and pure eraphite is the same, in the oxidizine and acidic media withgood corrosion resistance. lt can resist hydrofluoric acid, bromine, aqua regia and other strong corrosive and oxidizing media.The device has high heat transfer efficiency and remarkable energy*saving effect, which is used to preheat the combustion ai orheat the process gas of certain processes, can save primary energy, the fuel saving rate can reach more than 30%, and canstrengthen the process and sienificantlyimprove the production capacity.

ADVANTAGES OF SILICON CARBIDE HEAT EXCHANGER PRODUCTS

HIGHTHERMALCONDUCTIVITY

The thermal conductivity of silicon carbide is several times higher than that of stainless steel, which means that siliconcarbide heat exchangers are more efficient in transferringheat, enablingrapid heat exchange.

HEAT-RESISTANT

Silicon carbide material can withstand high temperatures up to 1600 'c, which makes the silicon carbide heat exchanger inthe high-temperature environment can still work stably.

CORROSION RESISTANCE

Silicon carbide is extremely chemically stable and resistant to most acids, alkalis and salts, making it suitable for use in avarietyof harshindustrialenvironments.

LIGHTWEIGHTING

Compared to metal heat exchangers, silicon carbide heat exchangers are lighter in weight and easier to install andmaintain.

LONGERSERVICE LIVES

The wear-resistant nature of the silicon carbide material ensures that the heat exchanger maintains a low wear rate overlong periods of operation,thereby extending the life ofthe equipment.

FLEXIBILITYIN STRUCTURAL DESIGN

Heat exchanger designs can be customized for specific applications to accommodate different heat exchange conditionsand space constraints.

Specification

Production