global@hmeonline.com

Mon to Fri 09:00 – 17:30

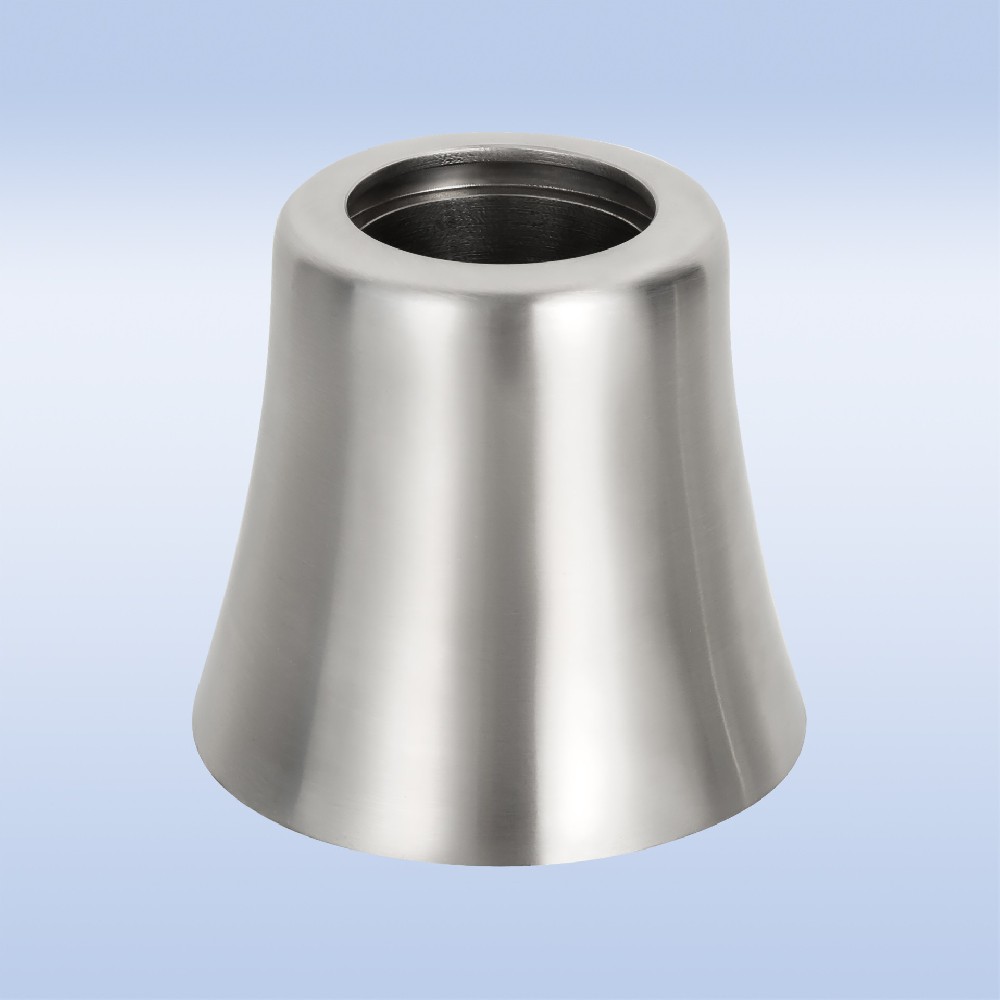

Various materials, customized processing according to customer needs.

Specification

Process design of precision castings

1、We design molds or drawings according to the samples provided by customers, and use CAE simulation pouring software to design the casting system.

2、Mold making: We make three-dimensional modeling of products according to samples or drawings, and use this three-dimensional drawing to make aluminum or steel molds.

3、Wax injection: Mix liquid wax and solid wax into a paste wax paste, inject the wax paste into the metal mold with a wax injection gun, and take out the wax mold after cooling.

4、Combination of wax parts: heat the stainless steel welding knife, and weld the wax mold on the gate rod according to the requirements of the process design.

5、Slime: Immerse the wax components in a tank containing water glass and other paints, and apply the paint.

6、Sand pouring: pour quartz sand on the coated wax component group, then immerse it in a hardening tank containing ammonium chloride and magnesium chloride and other materials to harden it, then dry it, and then proceed to the next layer of operation. This process is repeated about 6 times and then finished .

7、Dewaxing: Place the hardened wax components in the lost-wax tank, and heat them with steam to dissolve the wax, leaving the sand mold shell.

8、Mold shell roasting: The mold shell is placed in a roasting furnace to increase its strength.

9、Casting: Put the raw materials into the intermediate frequency electric furnace to melt, add metal element to formulate the material, the molten steel temperature rises to about 1600 degrees, and after the chemical analysis before the furnace is qualified, pour the molten molten steel into the mold shell through the ladle, let the steel The liquid fills the cavity and then cools, and samples are taken for final inspection after the furnace.

10、Shell removal: The sand on the surface of the casting is removed by vibration.

11、Cutting: The casting is cut from the casting rod with an oxygen-acetylene flame.

12、Grinding: Grind off the pouring riser with a grinder; polish the bad surface with a polisher.

13、Heat treatment: The castings are subjected to heat treatment such as normalizing, annealing, quenching and tempering, induction hardening, carburizing, and nitriding according to the material requirements.

14、Machining: CNC machining is performed according to the drawing requirements.

15、Final inspection: use tensile tester, impact tester, hardness tester and other testing equipment to test the mechanical properties of the test bar; use X-ray, ultrasonic, magnetic particle inspection and other testing equipment to perform non-destructive testing on the sample; use three coordinates and measuring tools and Checking tools such as calipers are used to finalize the size inspection of the product.

Production