global@hmeonline.com

Mon to Fri 09:00 – 17:30

Automatic forging production line for ring parts

Specification

The automatic forging production line of ring parts is composed of a loading and reclaiming machine for handling raw materials, an oil press used to open blanks, a manipulator for handling and positioning blanks, a CNC radial axial ring milling machine for ring rolling, a manipulator for moving out of ring parts, and a correction press for correcting the warping of ring parts. The production line can realize the linkage operation control between the single machine, and the blank ring parts can be automatically transported, handled, positioned and rolled, and the online detection can be realized, and the forging process of the ring parts can be automated. The production line can be networked with the management of the factory, the display terminal can monitor the operating status of the production line, if the monitor monitors the fault, can notify the on-site maintenance personnel through the network in time for maintenance

Non-standard products, customized according to customer requirements

Production

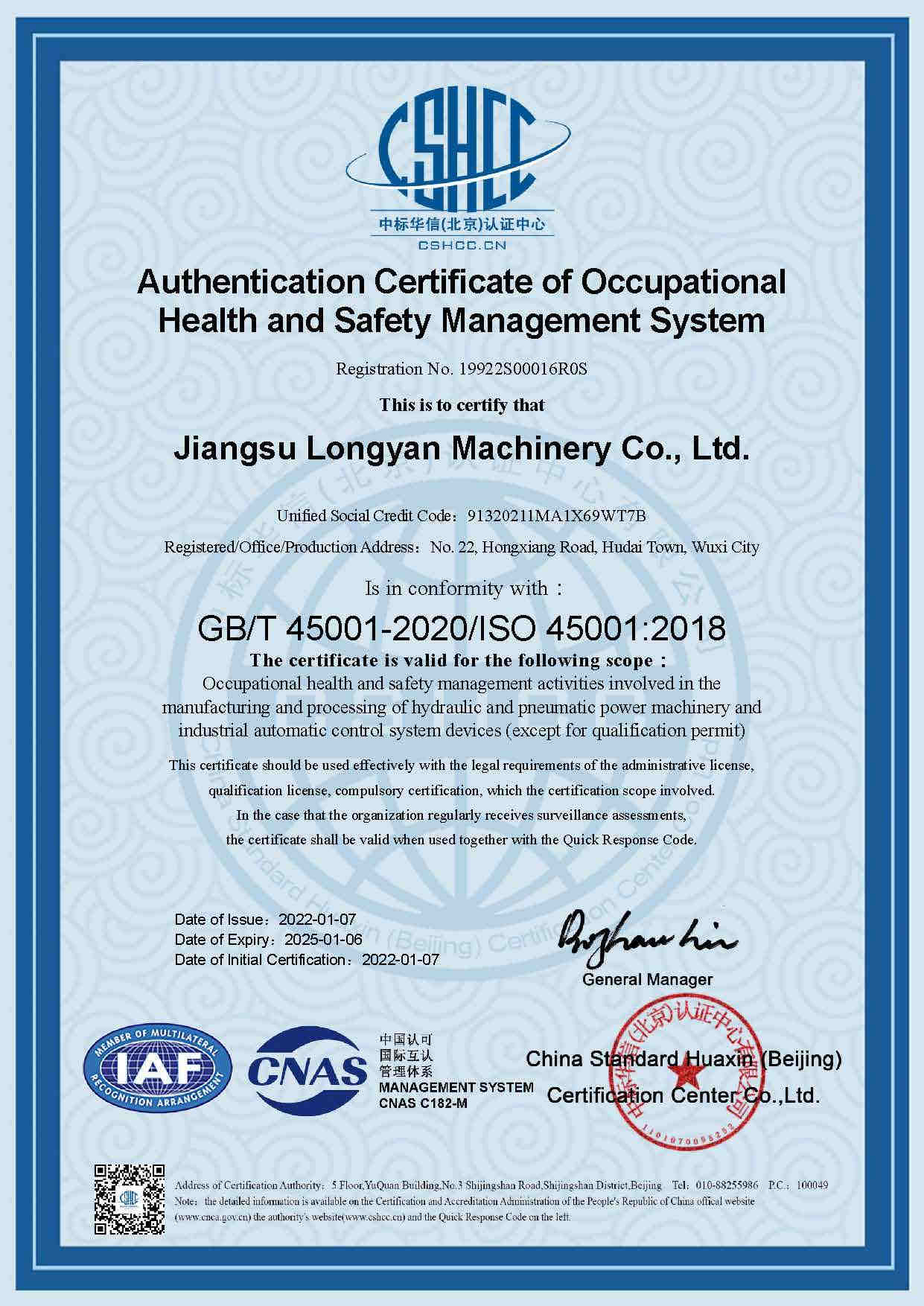

Qualification