global@hmeonline.com

Mon to Fri 09:00 – 17:30

Disc continuous dryer is a kind of conductive continuous drying equipment. Its unique structure and working principle determine that it has the characteristics of high thermal efficiency, low energy consumption, small footprint, simple configuration, convenient operation and control, and good operating environment.

It is widely used in chemical, pharmaceutical, pesticide, food, feed, agricultural Drying operations in industries such as by-product processing. It is well received in the practice of various industries. Now we manufacture three types of atmospheric pressure, airtight and vacuum, 1200, 1500, 2200, 3000, A (carbon steel), B (stainless steel evenly distributed in the contact material), C (on the basis of B, add a steam pipe The road, the main shaft and the bracket are made of stainless steel, and the cylinder and the top of the cover are lined with stainless steel).

Three kinds of materials, drying area of 4-180m2, a total of hundreds of models of series products, and can provide a variety of auxiliary equipment to meet the needs of users for drying various materials.

Feature

(1) Easy To Control And Strong Applicability

Optimize the drying process by adjusting the thickness of the material layer, the rotational speed of the main shaft, the number of rake arms, the type and size of the rake blades.

Each layer of drying tray can pass through the heating medium or cold medium separately to heat or cool the material, and the temperature of the material can be controlled accurately and easily.

The residence time of the material can be adjusted.

The flow direction of the material is single, there is no back-mixing phenomenon, the drying is uniform, the quality is stable, and no further mixing is required.

(2) Simple And Easy Operation

The operation of starting and stopping the dryer is very simple.

After the feeding is stopped, the conveying material scale rakes can quickly empty the material in the dryer.

Through the special large inspection door's sight glass, the inside of the equipment can be cleaned and observed very carefully.

(3) Low Energy Consumption

The material layer is very thin, the spindle speed is low, the power required by the material conveying system is small, and the power consumption is low.

Drying by conduction heat, high thermal efficiency and low energy consumption.

(4) The Operating Environment Is Good, The Solvent Can Be Recycled, And The Dust Emission Meets The Requirements

Normal pressure type: Due to the low airflow speed in the equipment and the high and low humidity distribution in the equipment, it is difficult for dust to float to the top of the equipment, so the exhaust gas discharged from the top moisture outlet contains almost no dust.

Airtight type: Equipped with a solvent recovery device, which can easily recover the organic solvent in the moisture-carrying gas. The solvent recovery device is simple and the recovery rate is high. For flammable, explosive, toxic and oxidizable materials, nitrogen can be used as a moisture-carrying gas for closed-circuit circulation to make it safe to operate. Especially suitable for drying flammable, explosive and toxic materials.

Vacuum type: The tray dryer operates in a vacuum state, especially suitable for drying heat-sensitive materials.

(5) Easy Installation And Small Footprint

The dryer is shipped as a whole and transported as a whole. It only needs to be hoisted into place, and the installation and positioning are very easy.

Due to the layered arrangement and vertical installation of the drying trays, even if the drying area is large, the floor space is small.

Application

Dehydrated vegetables, pellet feed, monosodium glutamate, grated coconut, organic plastics, synthetic rubber, propylene fibers, medicines, medicinal materials, small wood products, plastic products, aging and curing of electronic components, etc.

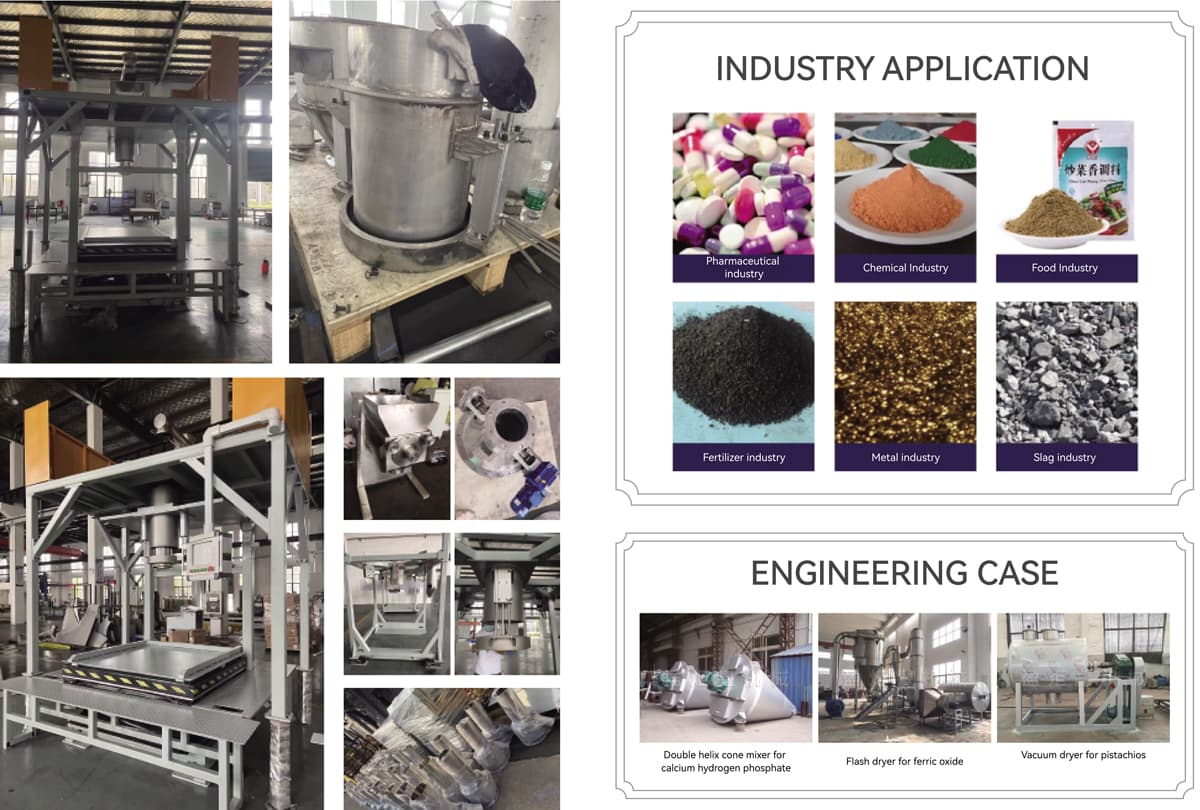

Production