global@hmeonline.com

Mon to Fri 09:00 – 17:30

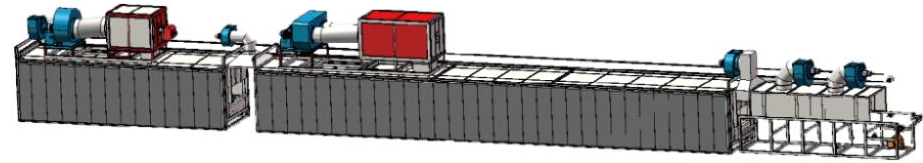

Equipment specification

1.Feeding SectionDischarge Section: Made of profiles through welding, provide a base to unload the workpiece and install the mesh belt transmission mechanism.

2.Cooling system: Includes profiles, plank, cooling exhausted machine, cooling fans which used for cooling workpiece from curing furnace. It is easy to unload the material, and it accelerate production cycle.

3.Mesh belt transmission mechanism:It is made of stainless steel mesh belt, big-pitch chains (δ=5.0), driving shaft, driven shaft, driving sprocket, drive section, and so on. It adopts inverter frequency control to adjust speed, which enables the continuous transmission from feeding, pre-curing, curing, and cooling to discharging.

4.curing furnace: it includes furnace body, furnace doors, hot air circulating system, exhaust system, supplemental oxygen system, combustion furnace steel platform, electrical control system.

5.Feeding SectionDischarge Section: Made of channel steel and profiles through welding, provide a base to unload the workpiece and install the mesh belt transmission mechanism

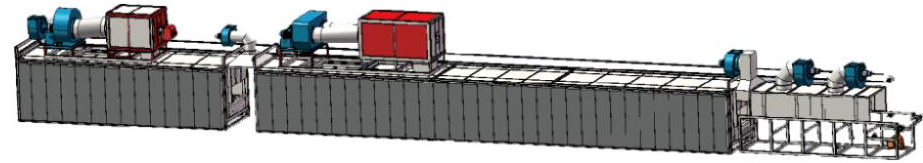

Specification

| Type Parameters | 1000-1200mm |

| Maximum size of workpiece | 1100mmx600mm |

| Boundary Dimension | 30000mmx2150mmx3782mm ( Can be customized.) |

| Maximum heating Volume | 10/40 thousand kcal/h |

| Speed of mesh belt | 0~0.7m/min |

| The maximum gas consumption | 40-50m³/h |

| The average consumption of gas | 45m³/h |

| Drive power | 2.2-5.5kw |