global@hmeonline.com

Mon to Fri 09:00 – 17:30

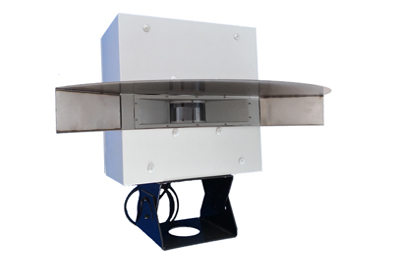

Kiln shell infrared scanning system is an infrared line scanner system purposely designed for rotary kiln shell temperature monitoring application. This system enables accurate non-contact kiln shell temperature monitoring, lining and coating thickness evaluation and live-ring migration.

It uses infrared sensor to check the temperature continuously of all areas of a kiln to create a thermal profile of the kiln. lts a complete solution for kiln shell monitoring. Our infrared scanning system defines a new generation of infrared measuring technology based on WINDOWS operating system.

This system is used for cement rotary kiln Alumina furnace, lime furnace, pelleting furnace and chemical fertilizer furnace.

Feature

The scanning frequency is adjustable from 20Hz to 50Hz.

The scanning system uses the most advanced interface port USB2.0 to transmit the infrared data. The data are transmitted steadily while the speed is up to 480Mbps.

The integrated circuit inside of thproducapplies advanced SCM.

Specification

| Standard Temperature Range | 100°C-600°C |

| Optical Resolution (SRF@90%) | 256:1 |

| Spot-Detection (SRF@50%) | 300:1 |

| Spectral Range (No Filter) | 3.5-4 |

| Scanning Manner | optics linear scanning |

| Scanning Rate (Scan-Speed) | 20-50Hz |

| Scanning Degree | 90° |

| Measurement Accuracy | ±1% or ±1℃ |

| Repeatability | ±1% or ±1℃ |

| IR-Detector Type, Te-Cooler | HgCdTe |

| Scanning Dots | 3072 dot / line |

Production