global@hmeonline.com

Mon to Fri 09:00 – 17:30

H-2 motor driver is suitable for 42, 57 two-phase stepping motors.

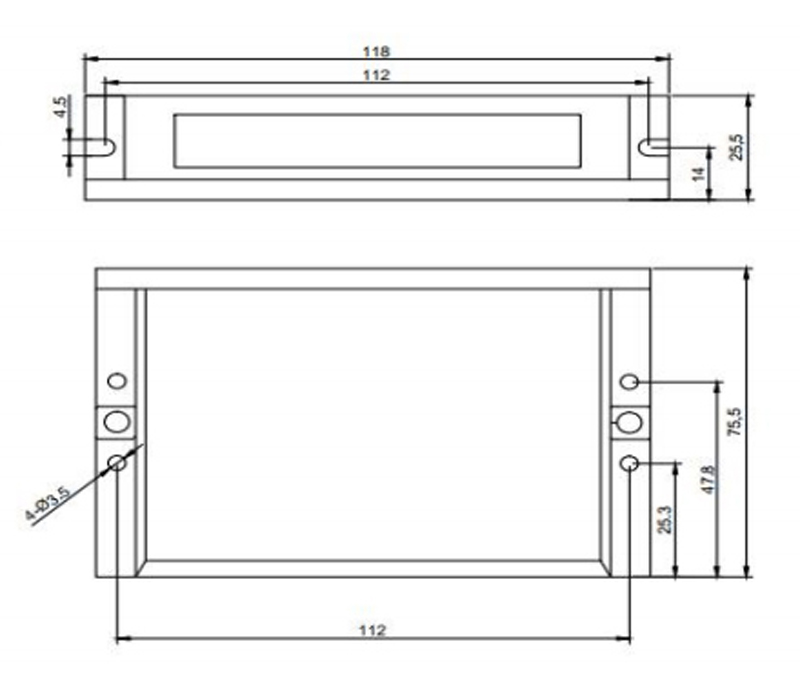

Side installation is recommended for better heat dissipation.

When installing the design, it is necessary to consider the size of the terminal block and the space required for heat dissipation.

With protection functions such as overvoltage and short circuit.

Feature

1. 32-bit DSP technology

2. Ultra-low vibration and noise

3. 4-digit dial, adjustable 16-level subdivision

4. Power-on automatic tuning, optional dial

5. Precise current control greatly reduces the heating of the motor

6. Support single and double pulse, dial selection

7. At rest, the current is automatically halved, and SW4 selects

8. Can drive 4, 6, 8-wire two-phase stepping motor

9. Optically isolated differential signal input

10. The highest impulse response frequency is 200KHZ

11. The current setting is convenient, and can be arbitrarily selected between 0.3-2.2A (peak value)

12. With protection functions such as overvoltage and short circuit

13. External alarm output, maximum initial current 100mA, withstand voltage 24Vdc

Specification

Minimum Value | Rated Value | Maximum Value | |

Output Current (Peak Value)(A) | 1 | / | 2.2 |

Output Voltage(V) | 20 | 24 | 50 |

Control Signal Input Current(mA) | 7 | 10 | 16 |

Step Pulse Frequency(KHz) | 0 | / | 200 |

Insulation Resistance(MΩ) | 100 | ||

Cooling Method | natural cooling or forced air cooling | ||

Using Occasions | it cannot be placed next to other heat-generating equipment. Avoid dust, oil mist, corrosive gas, high humidity and vibration places. Combustible gas and conductive dust are prohibited. | ||

Operating Temperature(°C) | 0-50 | ||

Humidity(RH) | 40-90% | ||

Using Vibration(Hz/mm) | 10-55 / 0.15 | ||

Temperature Maintenance(°C) | -20-65 | ||

Weight(g) | 230 | ||