global@hmeonline.com

Mon to Fri 09:00 – 17:30

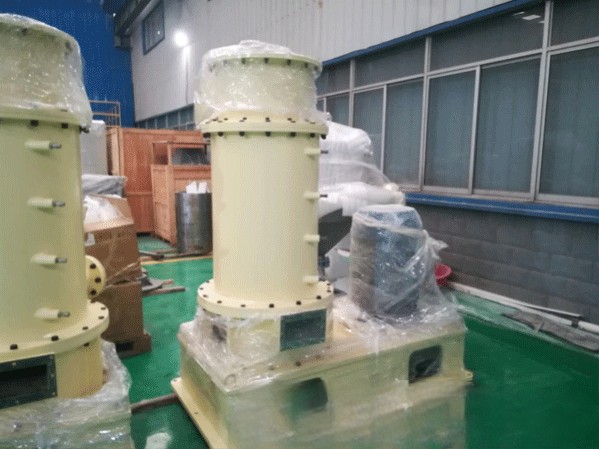

Excellent wet grinding and dry grinding process

1. Single-stage open-circuit grinding is a very economical fine grinding process. The production line composed of one mill can grind 2 μ Products with m ≤ D92.

2. The multi-stage grinding process consists of two or three mills in series. In each stage of grinding, media balls with different diameters, specifications and specific gravity are added, which can be grinded twice at a time μ M ≥ D98 or above. The multi-stage grinding process is characterized by flexible changes. It can easily produce D60 and D90 products without adding any equipment.

3. WR-G5 series powerful crushing dryer is a unique design based on the reference of some drying equipment at home and abroad. It has high efficiency and good performance, and has the advanced level in the world.

After the slurry pump enters the main machine, it is instantly dried by the high-temperature air entering under the feeding device. The material particles are dried on the one side and continuously crushed by the high-speed crusher on the other side. The size of the material particles is continuously reduced. Under the action of hot air, the fine powder and small particle materials are carried to the upper classification device. Because of the downward pressure and centripetal force generated by the rotation of the classification device (the rotating speed is adjustable), the particle materials are thrown down to the inner wall of the drying section and settled to the crushing device for further crushing and drying, The dried fine powder is collected by the dust collector through the grading device.

1、 Design scope

On the premise of meeting the annual output of users and having surplus, 325 mesh (<45 μ M The passing rate is 98%) opal shale dry powder is used as raw material, and the main design work scope includes automatic batching system, PLC central control system, low-voltage electrical control, mixing and dispersion, mechanical grinding, auxiliary viscosity reduction system, vibration screening, slurry transportation, heat source, drying, dispersion, collection, dust removal, cooling, sewage system, finished product storage, etc, The whole system starts from the receiving hopper of opal shale powder dry powder in the plant to the packaging of ultra-fine opal shale powder finished products, including the production facilities and basic auxiliary facilities necessary for the production line (except for the part responsible by the owner).

Specification

Production