global@hmeonline.com

Mon to Fri 09:00 – 17:30

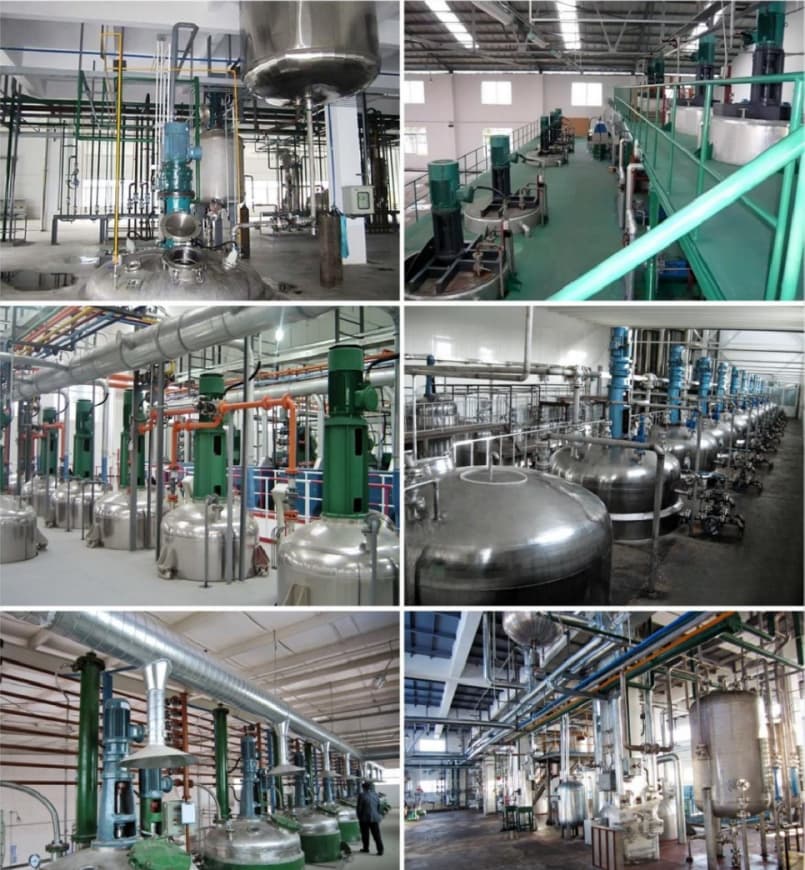

The equipment is composed of reaction kettle, dilution kettle, vertical cooling, fractionation column, elbow, horizontal cooling, waste water receiving tank, dilution kettle condenser, styrene receiving tank, etc. The product specifications are (reactor volume) 50L, 100L, 300L, 500L, 1000L, 2000L, 3000L, 6000L, 10000L, 15000L, 20000L, 30000L, or customized according to customer requirements.

Specification

Feature

1、The reaction kettle absorbs foreign technology, cancels the external jacket, and uses the internal coil tube for heating, so the heat exchange effect is better, avoiding the common problem that the domestic resin plant mistakenly operates the kettle and easily shrinks; Moreover, after the jacket is removed, the energy is greatly saved. When heating, because the coil is in the kettle, and the coil is 100% in contact with the material, the heat exchange effect is very good, and there is no short flow or serial flow. The jacket will have a gap with the inner cylinder when making, and the space is also large, in which the jacket oil accounts for about 65%. The energy can be saved by more than 50% after canceling the jacket; The weight of the equipment is also reduced, which can reduce the bearing of the equipment and save its construction cost;

2、The application of foreign advanced fractionation technology and the improved fractionation column can fully separate and reuse the organic steam, minimize the loss of raw materials, not only reduce the loss, but also greatly reduce the difficulty of later polycondensation wastewater treatment;

3、When the dilution kettle is diluted, a special disperser is used, which can be evenly distributed instantly to prevent agglomeration and agglomeration, and the quality is better;

4、The addition of condenser in the dilution kettle can minimize the volatilization of styrene and achieve the effect of environmental protection and energy conservation;

5、All the bottom bearings of the agitator kettle are equipped with worn steel sleeves to avoid long-term wear and damage to the agitator shaft, avoid shaft replacement, and reduce future maintenance costs;

6、Compared with the original wastewater distillation tower, the new wastewater distillation tower has the characteristics of large treatment capacity, low energy consumption, high treatment efficiency, lower COD of wastewater after distillation treatment, and simple operation.

7、Through the comprehensive utilization of boiler tail gas, reaction equipment waste heat, and the reuse of waste water organics, the whole set of equipment has greatly reduced the operating cost and made the products more competitive.

8、The equipment is composed of reaction kettle, dilution kettle, vertical cooling, fractionation column, elbow, horizontal cooling, waste water receiving tank, dilution kettle condenser, styrene receiving tank, etc. The product specifications are (reactor volume) 50L, 100L, 300L, 500L, 1000L, 2000L, 3000L, 6000L, 10000L, 15000L, 20000L, 30000L, or customized according to customer requirements.

Production