global@hmeonline.com

Mon to Fri 09:00 – 17:30

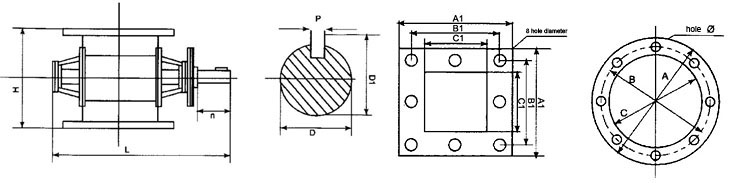

The BZRL stainless steel chain-driven rotary feeder can be used as a feeding device to realize the pneumatic dilute-phase conveying process of materials under positive pressure conditions.

The discharge volume can be easily adjusted by adjusting the sprocket.

The structure of the rotary valve adopts anti-jamming measures. The joint between the shell and the impeller adopts a prominent oblique seam. When large particles pass through, the protruding oblique seam can push it aside to make the impeller rotate smoothly.

According to the characteristics of the powder and the different operating conditions, the impeller structure can be open at both ends or closed at both ends, it can be a non-standard design with a deep cavity or a shallow cavity, or a special easy-to-disassemble and clean structure for attachment materials.

Specification

| Model | Volume Per Revolution | Installation Connection Size | ||||||||||||

| A | B | C | A1 | B1 | C1 | n | D | P | D1 | H | E | Hole Diameter(mm) | ||

| Type 2 | 2 liters/rev | 240 | 200 | 150 | 240*240 | 200*200 | 150*150 | 30 | 25 | 8 | 28 | 240 | 425 | 8-Φ11 |

| Type 4 | 4 liters/rev | 280 | 240 | 180 | 270*270 | 230*230 | 180*180 | 40 | 30 | 8 | 33 | 280 | 510 | 8-Φ11 |

| Type 6 | 6 liters/rev | 300 | 260 | 200 | 290*290 | 250*250 | 200*200 | 40 | 30 | 8 | 33 | 300 | 530 | 8-Φ11 |

| Type 8 | 8 liters/rev | 320 | 280 | 220 | 310*310 | 270*270 | 220*220 | 40 | 30 | 8 | 33 | 320 | 550 | 8-Φ11 |

| Type 10 | 10 liters/rev | 340 | 300 | 240 | 330*330 | 290*290 | 240*240 | 55 | 35 | 10 | 39 | 340 | 580 | 8-Φ13 |

| Type 12 | 12 liters/rev | 360 | 320 | 260 | 350*350 | 310*310 | 260*260 | 55 | 35 | 10 | 39 | 360 | 600 | 8-Φ17 |

| Type 14 | 14 liters/rev | 380 | 340 | 280 | 370*370 | 330*330 | 280*280 | 55 | 35 | 10 | 39 | 380 | 620 | 8-Φ17 |

| Type 16 | 16 liters/rev | 400 | 360 | 300 | 400*400 | 350*350 | 300*300 | 55 | 40 | 12 | 44 | 400 | 640 | 8-Φ17 |

| Type 18 | 18 liters/rev | 420 | 380 | 320 | 420*420 | 370*370 | 320*320 | 55 | 40 | 12 | 44 | 420 | 660 | 8-Φ17 |

| Type 20 | 20 liters/rev | 440 | 400 | 340 | 440*440 | 390*390 | 340*340 | 55 | 40 | 12 | 44 | 440 | 680 | 8-Φ17 |

| Type 26 | 26 liters/rev | 520 | 460 | 400 | 510*510 | 450*450 | 400*400 | 55 | 40 | 12 | 44 | 520 | 740 | 12-Φ17 |

| Type 30 | 30 liters/rev | 550 | 500 | 440 | 550*550 | 495*495 | 440*440 | 65 | 50 | 16 | 56 | 550 | 780 | 12-Φ17 |

| Type 40 | 40 liters/rev | 620 | 558 | 500 | 620*620 | 558*558 | 500*500 | 65 | 50 | 16 | 56 | 620 | 850 | 12-Φ17 |

| Type 50 | 50 liters/rev | 650 | 600 | 540 | 650*650 | 600*600 | 540*540 | 65 | 50 | 16 | 56 | 650 | 890 | 12-Φ17 |

Diagram

Production

Qualification