global@hmeonline.com

Mon to Fri 09:00 – 17:30

Specification

Explosion-proof parallel single-phase electric trace zone can be cut according to the actual needs of the length of use, when heating can be selected to design with explosion-proof thermostat thermocouple and other supporting use, can precisely set the control medium temperature, to achieve automatic control, can be widely used in pipelines, instruments, valves, small storage tanks, pump body insulation, antifreeze, heating. It is widely used in petroleum, chemical industry, electric power, metallurgy, light industry, food, freezing, construction, gas, agricultural and sideline products production, processing and other sectors.

1. Explosion-proof Single-phase Parallel Heating Cable

Explosion-proof single-phase parallel heating cables are ‘cut-to-length’. Explosion-proof temperature controllers are available. They can accurately and automatically control the process temperature, being widely used in temperature maintenance, freeze protection for the pipelines, instruments, valves, small-sized storage tank and pump. Can be used in hazardous locations, including options for Division 1 and Division 2. Other special specifications can be customized.

Characteristics:Cut-to-length, maintain high temperature, maximum temperature to 180℃

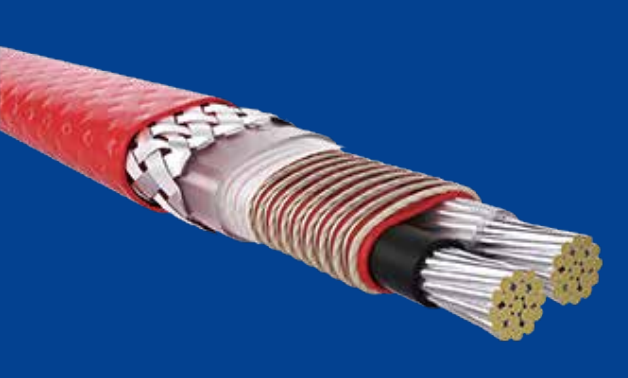

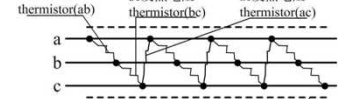

The bus wire is composed of two parallel insulated copper wires wrapped with PTC heaters. PTC heaters are alternative connection to the bus wire, which forming parallel resistance. Connected with 220 voltage current, then the parallel resistance begin to produce heat (see picture 1&2).

Structure

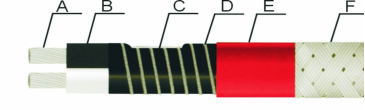

Conventional Type

A-bus wire (nickel-plated copper bus wires)

B-insulation layer (fluoroplastic)

C- compages

D-nichrome wire

E-insulated jacket(fluoroplastic

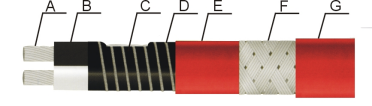

Reinforced Type

A- bus wire(nickel-plated copper bus wires)

B- insulation layer(fluoroplastic)

C- compages

D-nichrome wire

E-insulated jacket(fluoroplastic 46)

F-tinned copper braid

G-over jacket(fluoroplastic

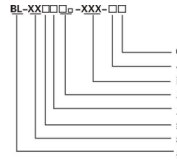

| Rated voltage | (w/m)Rated power | (m)Max length | øMax fluid temp | |

| BL-15FPV2-205-J(Q) | 220 | 15 | 220 | 130 |

| BL-20FPV2-205-J(Q) | 220 | 20 | 165 | 130 |

| BL-25FPV2-205-J(Q) | 220 | 25 | 132 | 130 |

| BL-30FPV2-205-J(Q) | 220 | 30 | 110 | 130 |

| BL-35FPV2-205-J(Q) | 220 | 35 | 94 | 130 |

| BL-40FPV2-205-J(Q) | 220 | 40 | 82 | 130 |

| BL-45FPV2-205-J(Q) | 220 | 45 | 73 | 130 |

| BL-50FPV2-205-J(Q) | 220 | 50 | 66 | 130 |

| BL-60FPV2-205-J(Q) | 220 | 60 | 55 | 130 |

| BL-20FPV2-260-J(Q) | 220 | 20 | 165 | 180 |

| BL-30FPV2-260-J(Q) | 220 | 30 | 110 | 180 |

| BL-40FPV2-260-J(Q) | 220 | 40 | 83 | 180 |

Fluid maximum maintenance temperature refers to the maximum process temperature. Generally, the temperature should not exceed the data in the above table.

Normal insulation resistance: ≥50MΩ/km

Dielectric strength: ~2000V/1min

Material of insulation layer: F46fluoroplastic 46

Maximum withstand temperature: 205℃

Explosion-proof marking: ExeⅡT4

Protection level: IP54

Explosion-proof certificate number: Please see specific certificate

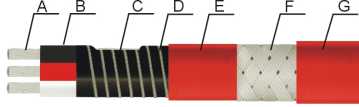

In addition to having characteristics of single-phase heating cable, explosion-proof three-phase heating cables are especially suitable for large diameter and long length pipe and can balance the power load.

A-bus wire (nickel-plated copper bus wires)

B- insulation layer (fluoroplastic)

C- compages

D-nichrome wire

E-insulated jacket(fluoroplastic 46)

F- tinned copper braid

G-over jacket(fluoroplastic 46)

tinned copper braid

Specification

| Catalog number | (V)Rated voltage | (w/m)Rated power | (m)Max length | ℃Max fluid temp |

| BL-25FPV3-205-J(Q) | 380 | 25 | 396 | 130 |

| BL-30FPV3-205-J(Q) | 380 | 30 | 330 | 130 |

| BL-35FPV3-205-J(Q) | 380 | 35 | 283 | 130 |

| BL-40FPV3-205-J(Q) | 380 | 40 | 248 | 130 |

| BL-45FPV3-205-J(Q) | 380 | 45 | 220 | 130 |

| BL-50FPV3-205-J(Q) | 380 | 50 | 198 | 130 |

| BL-55FPV3-205-J(Q) | 380 | 55 | 180 | 130 |

| BL-60FPV3-205-J(Q) | 380 | 60 | 165 | 130 |

| BL-65FPV3-205-J(Q) | 380 | 65 | 152 | 130 |

| BL-30FPV3-260-J(Q) | 380 | 30 | 330 | 180 |

| BL-40FPV3-260-J(Q) | 380 | 40 | 248 | 180 |

| BL-50FPV3-260-J(Q) | 380 | 50 | 198 | 180 |

| BL-60FPV3-260-J(Q) | 380 | 60 | 165 | 180 |

ø Fluid maximum maintenance temperature refers to the maximum process temperature. Generally, the temperature should not exceed the data in the above table.

Normal insulation resistance: ≥50MΩ/km

Dielectric strength: ~2500V/1min

Max withstand temperature:205℃ 260℃

Explosion-proof marking: ExeⅡT4

Protection level: IP54

Explosion-proof certificate number: Please see specific certificate