global@hmeonline.com

Mon to Fri 09:00 – 17:30

Specification

Because the three-phase parallel electric tracing zone is limited by the maximum length of use, so in the longer pipeline heating, it is bound to increase investment due to numerous intermediate power supply, and the maintenance and management is not convenient, and the three-phase series electric tracing zone is specially suitable for the longer pipeline heating and insulation, a power supply point can be used for hundreds of meters, or even thousands of meters. And make up for the parallel electric tracing zone length is too long when the head and tail power deviation is large defect, to ensure that the head and tail heat evenly.

Explosion-proof Series Heating Cable

Parallel heating cable is limited to the using length, so there will be more intermediate power supply unit when parallel heating cable is used for long distance heat tracing. Therefore, it increases the expenses and the burden of maintenance. Series heating cable is especially suitable for long distance heat tracing. One power supply can be used as long as hundreds of meters. Moreover, series heating cable can uniformize the heat along the pipe. Connected with 380 voltage current, series heating cable can balance the power load. Temperature controller with Pt100 temperature sensor and monitoring can realize accurately automatic temperature control.

Structure Principle

Composed of three copper wires, one end of the bus wire/heater should be reliably connected by way of short-circuit, while the other end is connected to 380V current. Because of Q=0.24I2RT, it will constantly produce heat. According to the practical situation, three-phase heating cable can be designed as split type or integral type.

series single-phase heating cable(reinforced)

series two-phase heating cable(reinforced)

series three-phase heating cable(reinforced)

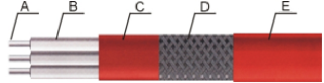

A- bus wire B- insulation layer C-outer jacket

D-tinned copper braid E- reinforced (anticorrosion) jacket

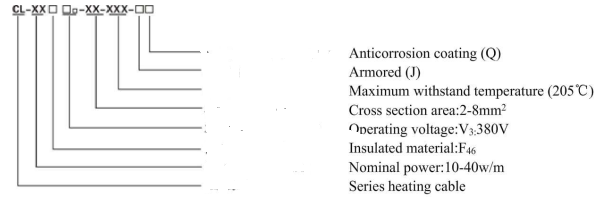

Catalog Number

Specification

Notice: per specifications are customized

Max fluid maintenance temperature refers to the maximum temperature of the pipe. Generally, it should not exceed the data in the above table.

normal insulation resistance: ≥50MΩ/km

dielectric strenghth: ~2000V/1min

max withstand temperature:205℃

explosion-proof marking: ExeⅡT4

protection level: IP54

explosion-proof qualification number: see qualification certificate