global@hmeonline.com

Mon to Fri 09:00 – 17:30

Japanese precision hobbing machine superhard processing;

Good running precision and good stability;

High efficiency, high input speed, high output torque;

Quiet, lightweight/small;

High rigidity, high precision, long life;

Freedom to install;

Input/output shaft integrated structure;

It can be applied to printing machines, laser cutting machines, CNC machine tools, lithium batteries, spring machinery, packaging machines, warp knitting machines, injection molding machines and other products.

Specification

| Reduction Ratio(i) | 25 | 30 | 35 | 40 | 45 | 50 | 60 | 70 | 80 | 90 | 100 | 120 | 140 | 160 | 180 | 200 |

| Rated Output Torque T2n (Nm) | 150 | 150 | 140 | 120 | 100 | 100 | 150 | 140 | 120 | 100 | 100 | 150 | 140 | 120 | 100 | 100 |

| Emergency Stop Torque (Nm) | triple rated output torque | |||||||||||||||

| Rated Input Speed (rpm) | 4000 | |||||||||||||||

| Maximum Input Speed (rpm) | 8000 | |||||||||||||||

| Ultra-precision Backlash P0 (arcmin) | ≤14 | |||||||||||||||

| Torsional Rigidity (Nm / arcmin) | 14 | |||||||||||||||

| Allowable Radial Force (N) | 2985 | |||||||||||||||

| Allowable Axial Force (N) | 1625 | |||||||||||||||

| Service Life (hr) | 20,000 (10,000 for continuous operation) | |||||||||||||||

| Efficiency(%) | ≥92% | |||||||||||||||

| Weight (kg) | 4.6 | |||||||||||||||

| Operating Temperature (℃) | -10℃-+90℃ | |||||||||||||||

| Lubricating | synthetic lubricants | |||||||||||||||

| Degree Of Protection | IP64 | |||||||||||||||

| Installation Direction | any direction | |||||||||||||||

| Noise Value (db(A)) | ≤65 | |||||||||||||||

| Moment Of Inertia (kg·cm²) | 0.35 | 0.31 | ||||||||||||||

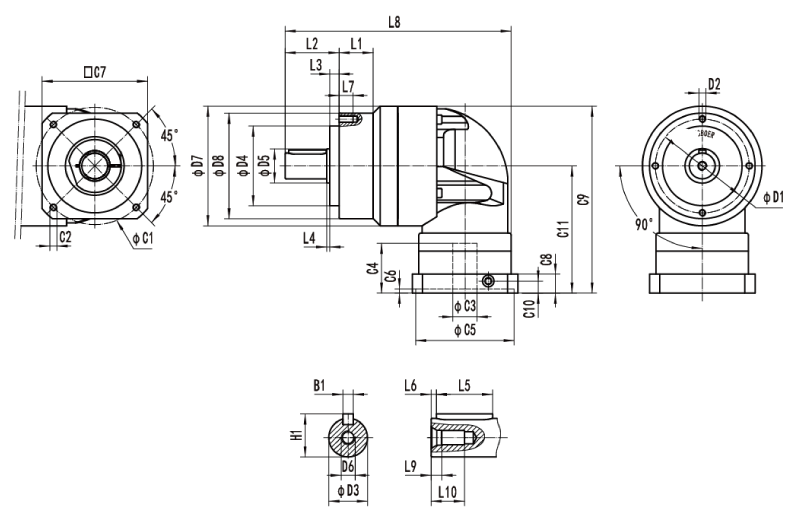

Diagram

| D1 | D2 | D3 | D4 | D5 | D6 | D7 | D8 | B1 | H1 | L1 | L2 | L3 | L4 | L5 | L6 |

| 80 | M6x1.0P | 22 | 68 | 30 | M8x1.25P | 104 | 90 | 6 | 24.5 | 33.5 | 46 | 8.5 | 1 | 32 | 3 |

| L7 | L8 | L9 | L10 | C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 | C9 | C10 | C11 | |

| 12 | 207.5 | 7.2 | 19 | 70 | M5x0.8P | ≤14 / ≤16 | 34 | 50 | 8 | 60 | 19 | 133.5 | 13.5 | 81.5 |

Production