global@hmeonline.com

Mon to Fri 09:00 – 17:30

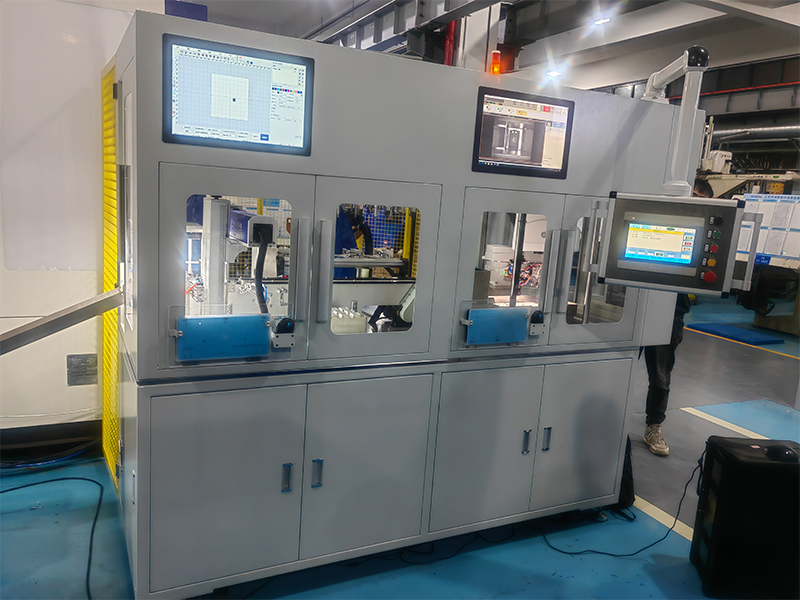

Widely used in: medical/automotive/3C electronics/home appliances/die-casting/stamping and other fields.

LDVision International Leading Algorithm + Al independently developed a complete image algorithm LDVision International leading detection accuracy, greatly improving production efficiency.

Using CCD or global exposure CMOS camera, high-definition imaging can quickly and accurately capture the production situation in the mold, accurately record defect information, automatically correct defect information, and can correct 10mm errors in high-definition imaging for efficient detection.

One mold monitor corresponds to the in-mold monitoring system of multiple injection molding machines, greatly saving procurement costs.

It can integrate the status parameters of all monitors and the real-time images of each camera and transmit them to the central server for remote viewing and management.

Specification

Core advantages of in-mold monitor:

| Mold monitor configuration and parameters | |

| Model | LD-850/VR-900/LD-950 (supports 1-6 3 million CCDs) |

| Screen size | 12.5 inches/full touch |

| CPU model | Celeron3855/3865/3955/7100/7200U |

| CPU frequency | 1.6/1.8/2.0/2.4/2.5-3.1GHz |

| Memory Capacity | 4G/8G |

| Harddisk | MSATA 64G/128G |

| Operating system | LINUX (embedded system) |

| Rated voltage | DC12V-35V |

| Overall weight | 1.8kg |

| Camera | Standard 3 million/5 million color CCD (supports manual switching between black and white and color) |

| Resolution | 1920*1080 |

| Frame rate | 30 |

| Sensor | 1/1.8”CCD |

| Communication method | Using RJ45 with POE Gigabit interface, the only one in China with the strongest anti-interference (USB communication is currently commonly used) |

Standard monitor LD-850:

| Standard configuration | Main configuration names and parameters | Device model | |||||

| Industrial host (i5-7/8G/1T) | Industrial camera (5 million pixels, black and white/color optional) | 1 camera | Industrial lens (zoom/fixed focus 5 million pixels) | Light source (Infrared visible light) | Magnetic base (10KG) | LD-CY900-1C | |

| 2 cameras | LD-CY900-2C | ||||||

| 3 cameras | LD-CY900-3C | ||||||

| 4 cameras | LD-CY900-4C | ||||||

Die-cast monitor LD-900:

| Standard configuration | Main configuration names and parameters | Device model | |||||

| Industrial host (i5-7/8G/1T) | Industrial camera (3 million pixels, black and white/color optional) | 1 camera | Industrial lens (zoom/fixed focus 3 million pixels) | Light source (Infrared visible light) | Magnetic base (10KG) | LD-YZ900-1C | |

| 2 cameras | LD-YZ900-2C | ||||||

Stamping monitor LD-950:

| Standard configuration | Main configuration names and parameters | Device model | |||||

| Industrial host (i5-7/8G/1T) | Industrial camera (5 million pixels, black and white/color optional) | 1 camera | Industrial lens (zoom/fixed focus 5 million pixels) | Light source (Infrared visible light) | Magnetic base (10KG) | LD-CY900-1C | |

| 2 cameras | LD-CY900-2C | ||||||

| 3 cameras | LD-CY900-3C | ||||||

| 4 cameras | LD-CY900-4C | ||||||

Production