global@hmeonline.com

Mon to Fri 09:00 – 17:30

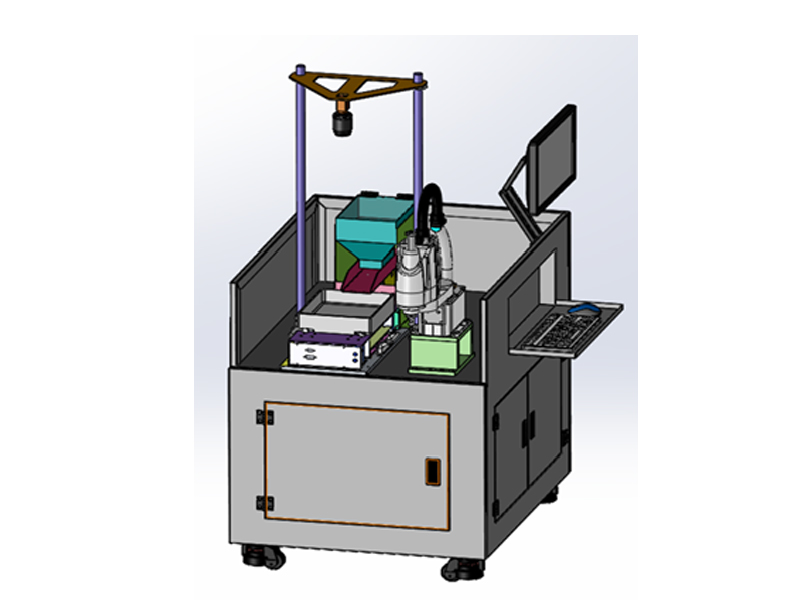

It is suitable for arranging and feeding 99% of small parts in industrial automation production; the feeding system does not need to change the hardware structure, and the program can be switched with one click; the fitting technology based on frequency vibration can judge and position the product posture through the visual system; Based on multi-directional vibration fitting technology, parts can be fed flexibly with extremely low damage. The parameter configuration of the flexible feeder is software-based, with a graphical interface, easy to configure and integrate, and can be easily integrated into various mainstream industrial automation equipment. PLC and robot vision system production system;

Specification

Function introduction of flexible feeding system:

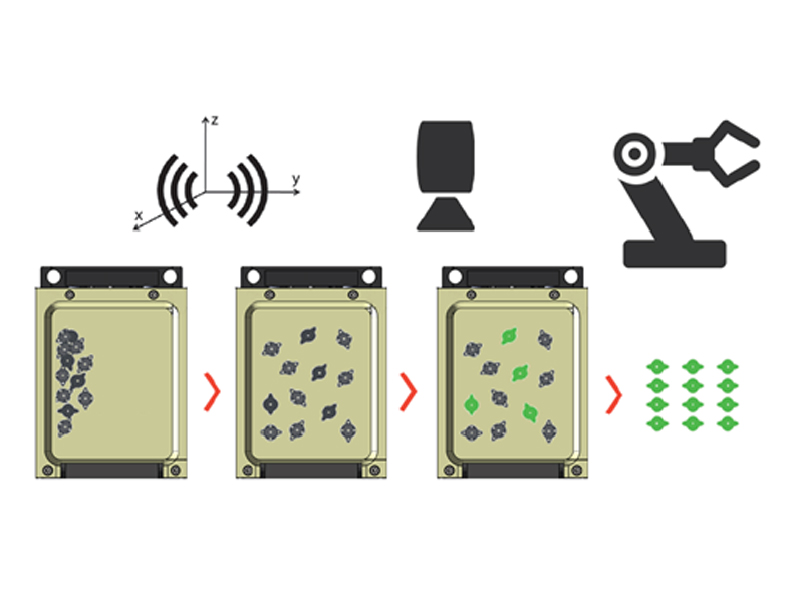

The resonance principle is used to achieve the process of moving materials in a certain direction to form an arrangement by using the resonance principle for fine parts with complex geometric shapes, sensitive materials and surfaces that are vulnerable, or with sizes of several millimeters or smaller, and the visual system is used to judge and position the product posture. Give the coordinate data to the robot, and the robot will grab based on the coordinate data. The bottom CCD will take pictures for secondary positioning. The robot will perform accuracy compensation and then perform array placement, palletizing or assembly operations as required.

| Standard Configuration | Main configuration names and parameters | |||

| Model LD-Vision 1.0 | Positioning module includes numerous key tools | Product position detection and overlapping elimination | Supports many camera models from 30W to 500W, and can carry up to one camera | |

| Model LD-Vision 2.0 | High-precision positioning module | Product position detection, overlapping elimination and precise positioning placement | Supports many camera models from 30W to 2500W, and can carry four cameras to run at the same time | |

| Model LD-Vision 3.0 | High-precision positioning + measurement + AI detection multi-module | Product position detection, product type judgment, product classification, overlapping elimination and precise positioning and placement | Supports many camera models from 30W to 2500W, can carry four cameras at the same time, and supports multiple robots running at the same time | |

Flexible loading station system-replenishing bin

| Standard configuration | Main configuration names and parameters | |||

| Model FBL02 | Silo size 302*190*140mm | Bin load capacity 5Kg | Applicable product size 0.5-1.5mm | |

| Model FBL05 | Silo size 400*220*165mm | Bin load capacity 8Kg | Applicable product size 0.5-30mm | |

Flexible loading station system-flexible vibrating plate

| Standard configuration | Main configuration names and parameters | |||

| Model RX200 | Silo size 200*180*26mm | Bin load capacity 5Kg | Applicable product size 0.5-1.5mm | |

| Model RX300 | Silo size 270*210*50 | Bin load capacity 8Kg | Applicable product size 0.5-30mm | |

Production