global@hmeonline.com

Mon to Fri 09:00 – 17:30

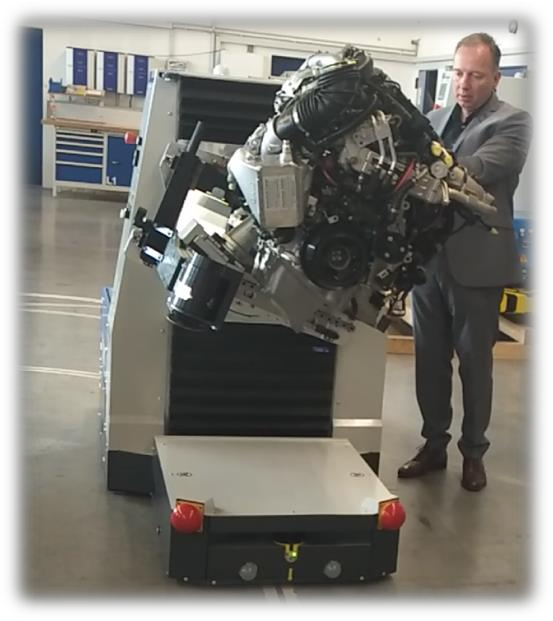

Project time: November 2018

Cumulative use area: 5000 square meters

Model used: P-1000

Number of AGVs: 35 units

Project description: This customer introduced AGV as the main platform for engine assembly, and evacuated the traditional engine production line to facilitate assembly by workers, and realized the automated online assembly function of AGV, which can interact with lineside robots and production equipment. AGV realizes At the same time as the beat is being assembled. Reduce the process and time of changing product lines of different models and categories.

Specification

| Rated load | 800kg |

| Number of wheels | 4N° |

| Steering angle (β) | 360° |

| Walking speed | 3km / h on flat surface, 2km / h on slopes |

| Travel motor*4 | 1kw / 48v |

| Special directional motor*4 | 0.2kw / 48v |

| Battery | 25Ah / 48v |

| Battery weight | 15kg |

| Driving wheel size*4 | Φ250×64mm |

| Climbing gradient (full load / no load) | 6% / 12% |

Application