global@hmeonline.com

Mon to Fri 09:00 – 17:30

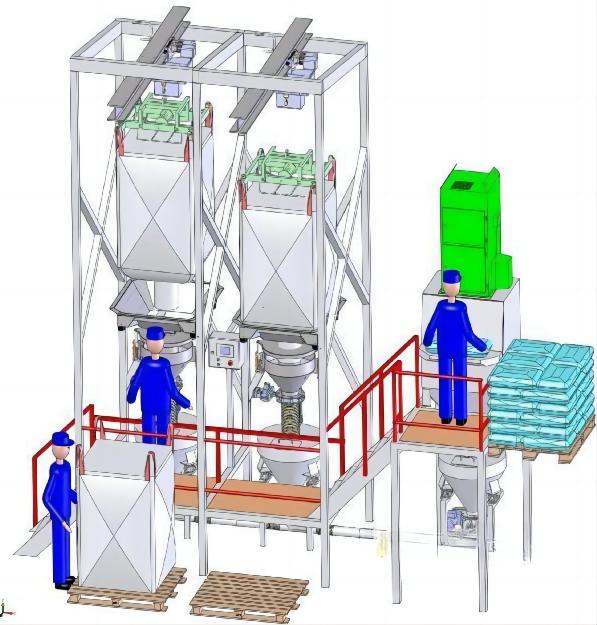

The combined feeding station is a new type of unpacking and unloading equipment developed by our company through summing up experience in the process of traditional powder unpacking and feeding. Its biggest feature is that it is suitable for unpacking and feeding of materials with two specifications: conventional ton bags and conventional 25KG small bags. It can unload 500-2000kg ton bags or 10-50kg granular powder. The equipment is used in chemical, plastic, rubber, food, medicine and other fields to unpack and unload dry powder and granular materials packaged in large bags or small bags at the same time.

Specification

characteristic

It can also be used for discharging conventional ton bags and small bags

The feeding station is simple in structure and convenient for workers to operate

The flapping device of the ton bag unloading mechanism can ensure the smooth blanking of materials

Auxiliary devices such as magnetic separation and vibration can be added as required

The equipment has its own dedusting device, which can effectively absorb the dust generated in the feeding process

Closed bag opening, dust flying during unloading, no heat generation, safe and environmentally friendly

Two modes of pneumatic or electric (hoist) control can be provided to adapt to different unloading environments

Applicable conditions: large bag packaging materials with good fluidity, moisture absorption and agglomeration

Applicable industries: plastics, rubber, food, medicine, chemical industry, building materials, coatings

Production

Qualification

Qualification