global@hmeonline.com

Mon to Fri 09:00 – 17:30

Product features:

The series pump is sealed with dry gas, and the flushing scheme often adopts Plan11/21+Plan72+76. The medium will not leak into the atmospheric environment. Usually, minor internal leaks need to be discharged into the flare system. When used in media with saturated vapor pressure lower than atmospheric pressure such as aromatic hydrocarbons and acetic acid, the flushing plan often adopts Plan 11/21+Plan 72+75

Typical applications: pumps for light hydrocarbons, aromatics, ethylene oxide, acetic acid, etc. in industries such as petrochemical and coal chemical.

Technical parameters:

Sealing chamber temperature: -40 ℃+176 ℃

Linear speed: ≤ 25m/s

Sealing chamber pressure: ≤ 60bar

Material combination:

Sealing surface: graphite, reactive silicon carbide, pressureless silicon carbide, tungsten carbide

Auxiliary sealing: nitrile rubber, fluorine rubber, ethylene propylene rubber, perfluorocarbon rubber

Spring and metal parts: 304316, Hastelloy alloy

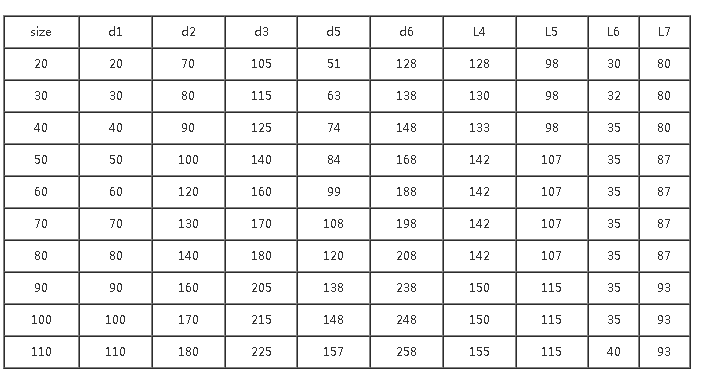

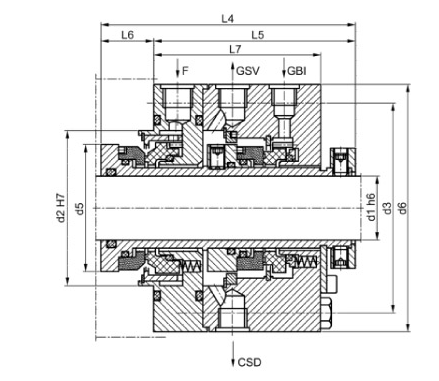

Specification