global@hmeonline.com

Mon to Fri 09:00 – 17:30

Product overview

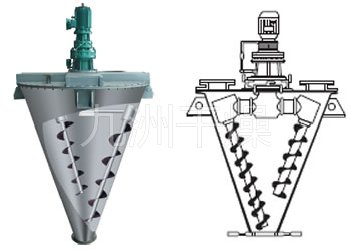

The compound movement of the material in the cone is caused by the rotation of the screw, and there are mainly four types of movement:

1. The screw revolves along the wall, making the material move in a circle along the cone wall;

2. The screw rotation makes the material move from the bottom of the cone Spiral rising;

3. The compound motion of the screw’s public and self-rotation makes part of the material be absorbed into the spiral cylindrical surface, and at the same time, under the centrifugal force of the screw’s rotation, part of the material in the spiral cylindrical surface is discharged radially to the cone;

4. The ascending material is absorbed Self-gravity is reduced. The four movements produce convection, shear, and diffusion in the mixer, so as to achieve the purpose of rapid and uniform mixing.

Equipment features

◎Flying knife can be added, spray and atomize assembly, to meet special process requirements.

◎The discharge valve has two modes: manual and pneumatic.

◎Special materials can increase the power of the motor (heavy type).

Scope of application Applied

to mixing and reacting powder and powder (solid-solid), powder and liquid (solid-liquid), liquid and liquid (liquid-liquid) in chemical industry, medicine, pesticide, dyestuff, petroleum, metallurgy, building materials, etc. , dry and cool.

Specification

| model | unit | DSH0.3 | DSH0.5 | DSH1 | DSH2 | DSH4 | DSH6 | DSH10 |

| full volume | ( m3 ) | 0.3 | 0.5 | 1 | 2 | 4 | 6 | 10 |

| loading factor | 0.4-0.6 | |||||||

| Mixed material particle size | (um) 40-3000 | |||||||

| working conditions | Normal temperature, normal pressure, dust seal | |||||||

| Output per time | (kg) | 180 | 300 | 600 | 1200 | 2400 | 3600 | 6000 |

| power | (kw) | 2.2 | 2.2 | 5.5 | 5.5 | 11 | 20.7 | 30.7 |

| mixing time | (min)4-10 (special materials are determined by tests) | |||||||

| Total Weight | (kg) | 500 | 1000 | 1200 | 1500 | 2800 | 3500 | 4500 |