global@hmeonline.com

Mon to Fri 09:00 – 17:30

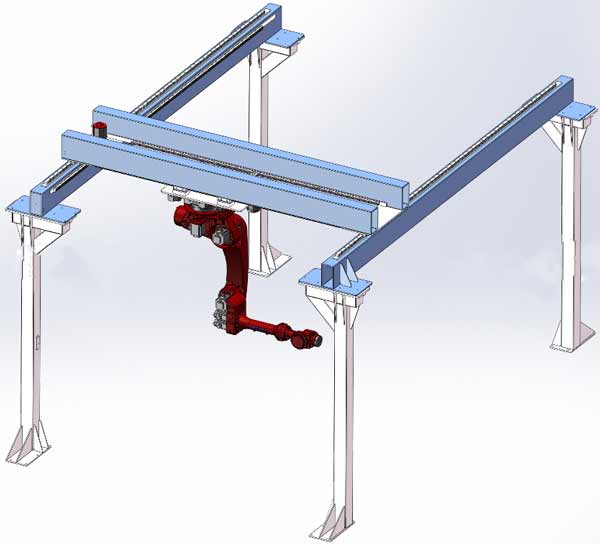

Truss manipulator is a kind of fully automatic industrial equipment based on the right angle X, Y, Z three-coordinate system to adjust the workpiece, or realize the trajectory movement of the workpiece. Its control core is realized through industrial controllers (such as: PLC, motion control, single-chip microcomputer, etc.). After making a certain logical judgment through the analysis and processing of various input (various sensors, buttons, etc.) signals by the controller, the execution command of each output component (relay, motor driver, indicator light, etc.) is issued to complete the joint movement between the X, Y, and Z axes, so as to realize a complete set of fully automatic operation process.

Feature

Truss manipulator is a kind of fully automatic industrial equipment based on the right angle

X, Y, Z three-coordinate system to adjust the workpiece, or realize the trajectory movement of

the workpiece. Its control core is realized through industrial controllers (such as: PLC, motion

control, single-chip microcomputer, etc.). After making a certain logical judgment through the

analysis and processing of various input (various sensors, buttons, etc.) signals by the controller,

the execution command of each output component (relay, motor driver, indicator light, etc.) is issued

to complete the joint movement between the X, Y, and Z axes, so as to realize a complete set of fully automatic operation process.

Production