global@hmeonline.com

Mon to Fri 09:00 – 17:30

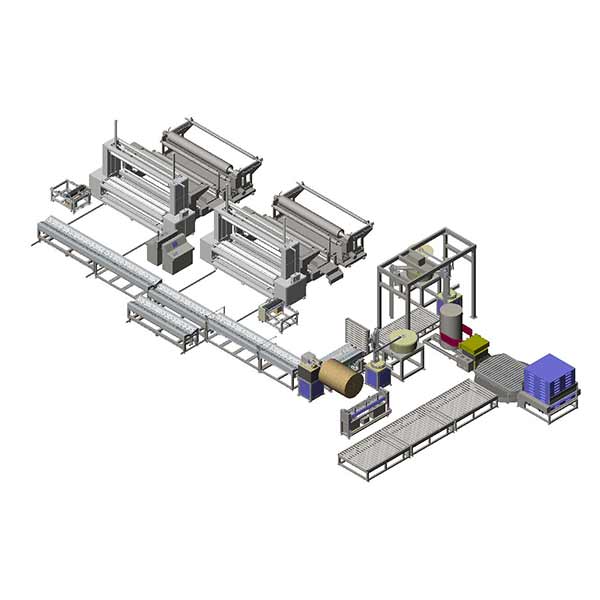

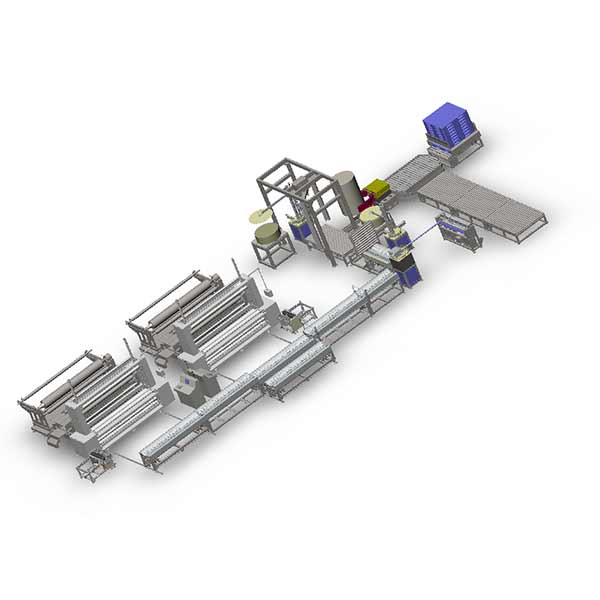

The integrated process of automatic bag loading, automatic sealing, packaging, labeling, automatic palletizing and conveying has a high degree of automation, good reliability and can realize unattended status.

Feature

The integrated process of automatic bag loading, automatic sealing, packaging, labeling, automatic palletizing and conveying has a high degree of automation, good reliability and can realize unattended status.

Non-woven automatic packaging line is based on the product characteristics of non-woven fabrics, production technology and other independent research and development design, through reasonable process flow arrangement, starting from docking slitting equipment, mainly to complete the turnover handling of non-woven products, robot automatic palletizing, automatic cardboard, automatic wrapping packaging, automatic weighing, automatic printing and labeling, automatic flipping off the line, warehousing, three-dimensional warehouse and other equipment to realize the whole plant automatic packaging line closing process; Through the use of the above automatic packaging system, the purpose of improving the rate, reducing labor intensity and saving labor can be achieved.

Generally speaking, the packaging equipment can realize the different packaging needs of large and small products, including: separate stretch film, stretch film and pearl cotton corner protection at the same time, the overall use of stretch film, the use of robot palletizing, not only can efficiently complete the palletizing operation, but also in the gripping of the cloth roll while grabbing cardboard protective cloth roll products, the whole line through the unique flip design can meet the packaging of a single tray of oversized products.

Production