global@hmeonline.com

Mon to Fri 09:00 – 17:30

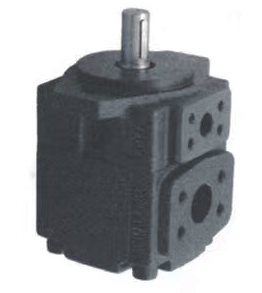

This series of pumps are high-pressure high-performance vane pumps specially developed for low-noise work. Unique design, high-precision machining and reasonable selection of materials ensure the advantages of high reliability and strong adaptability, and are most suitable for the needs of modern hydraulic systems. It is widely used in various hydraulic systems such as injection molding machines, pressure die casting machines, metal cutting machine tools, construction machinery and other types of hydraulic systems.

Feature

1. The arc blades with reasonable design and precision machining reduce the pressure of the blades on the inner curve of the stator and improve the service life of the stator and blades.

2. The stator adopts an advanced high-power non-impact transition curve, which makes the blade have a good movement and stress state, ensures a good contact between the blade and the stator, and minimizes flow loss, pressure and flow pulse, and reduces noise, longer life.

3. The side plate adopts hydraulic balance to obtain better volumetric efficiency.

4. The key parts are made of high-quality materials and advanced heat treatment process, and the overall reliability of the oil pump is further improved.

5. Adopt plug-in structure. The main internal parts are made into components, the pump core replacement can be completed in a few minutes, the interchangeability is good, and the maintenance is convenient.

Specification

| F- | PV2R2 | -47 | -F |

| Applicable Fluid Markings | Serial Number | Nominal displacement mL/r | Installation |

Unmarked Petroleum oil Emulsion water-glycol F: Phosphate ester liquid | PV2R1 | 6.8.10.12,14,17.19,23,25,28,31 | Type F:(standard); flange mount L: foot mount |

| PV2R2 | 26,33.41,47,53.59,65,75 | ||

| PV2R3 | 52,60,66,76,85,94,116,125,136,153 |

| F | -1 | R | -U | -10 |

| Port connection | Shaft extension | Choose direction | Output port location | Design |

F:SAE 4--Bolt connection S: Threaded connection | 1 (standard): Cylindrical shaft extension 2: Cylindrical shaft extension | Viewed from the shaft | number 10 | |

end R (standard): Clockwise direction L: Counterclockwise | U-above (standard) D: below R: right L: left | |||

Note

1. If you need other specifications of displacement or other types of shaft extension, please contact the technical department of our company.

2. The position of the suction port is designed to be above.

3. When the order model is incomplete, the product (installation type, shaft extension type, rotation direction and oil port position, etc.) shall be provided according to the standard type.