global@hmeonline.com

Mon to Fri 09:00 – 17:30

It is mainly used for weight transmission in the factory automation production process, especially suitable for high-precision fields such as down filling machines, cotton filling machines, liquid injection machines, and tablet presses.

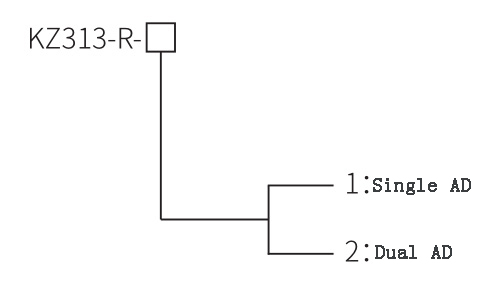

Dual AD channels.

Multi-stage dynamic digital filter to meet high-speed dynamic weighing occasions.

Display division: 500,000 divisions.

2 sensor interfaces, each supporting 4 350 ohm sensors.

Independent RS232 and RS485 dual serial communication interfaces.

400Hz / 200Hz / 100Hz sampling rate optional.

Specification

| Working Power Supply | DC24v(18-36V) |

| AD Type | 24 bit AD conversion (with analog and digital filtering), dual AD channel |

| Zero Drift | <0.02uV/℃ |

| Internal Resolution | 1 / 16000000 |

| Input Range | -10~30mV |

| Excitation Voltage | 5V |

| Communication Interface | COM1RS232, COM2RS485 |

| Weight Display | 6 bit LED display |

| Key Functions | 4 function keys |

| Operating Temperature | -10~50℃ |

| Power | Less than 6w |

| Sample Rate | Maximum 400 times / second |

| Nonlinear | 0.002%FS |

| Display index | 500,000 |

| Minimum Input | 0.2uV/d |

| Driving Capacity | Up to eight 350Q sensors can be driven |

| Temperature Coefficient | ≦5ppm/C° |

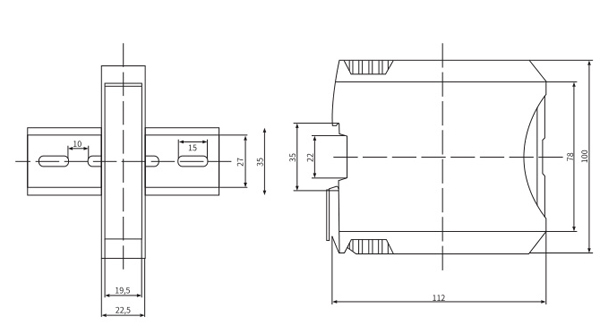

| Installation Method | Guide rail installation |

| Relative Humidity | 10~90%, non condensing |

Diagram

Qualification