global@hmeonline.com

Mon to Fri 09:00 – 17:30

Imported weighing originals are used.

Store formula data up to 10 groups.

Explosion-proof configuration, can be used in hazardous areas (optional).

Quantitative value can be manually set, suitable for filling of various specifications.

Applicable to a variety of container specifications, the quantitative value can be set, the application range is wider, the weighing out-of-tolerance alarm, and fault self-diagnosis.

Automatically judge the tare weight range and tare, and solve the impact of different container weights on accuracy.

The material contact part is made of 316 stainless steel, the others are made of 304 stainless steel, and the carbon steel plug is made of polytetrafluoroethylene anti-corrosion material.

RS232/484 interface is reserved as standard, and DP and MUDBUS bus are optional, which is convenient for computer data management.

Specification

| Filling Capacity | 50-300kg |

| Filling Speed | 300-1 single head 40~50 barrels / hour, 300-2 double heads 70~90 barrels / hour (200L) |

| Filling Accuracy | Class 0.2, ±0.1~0.2% |

| Weighing Device | Maximum weighing 300kg, scale value: 50g / 100g / 200g |

| Filling Container | Square / round drum, 200L iron drum, plastic drum, etc. |

| Operating Temperature | -10℃~45℃ |

| Relative Humidity | ≤95% |

| Working Power | AC380V / AC220V, 50HZ,<500W |

| Installation Requirements | Horizontally fixed on the concrete ground (the thickness of the concrete is required to be greater than 20mm) |

| Working Air Source | 0.4~0.6Mpa |

| Air Consumption | 10m³/h |

| Material Interface | DN40 standard flange, material inlet pressure: less than 6Mpa |

Application

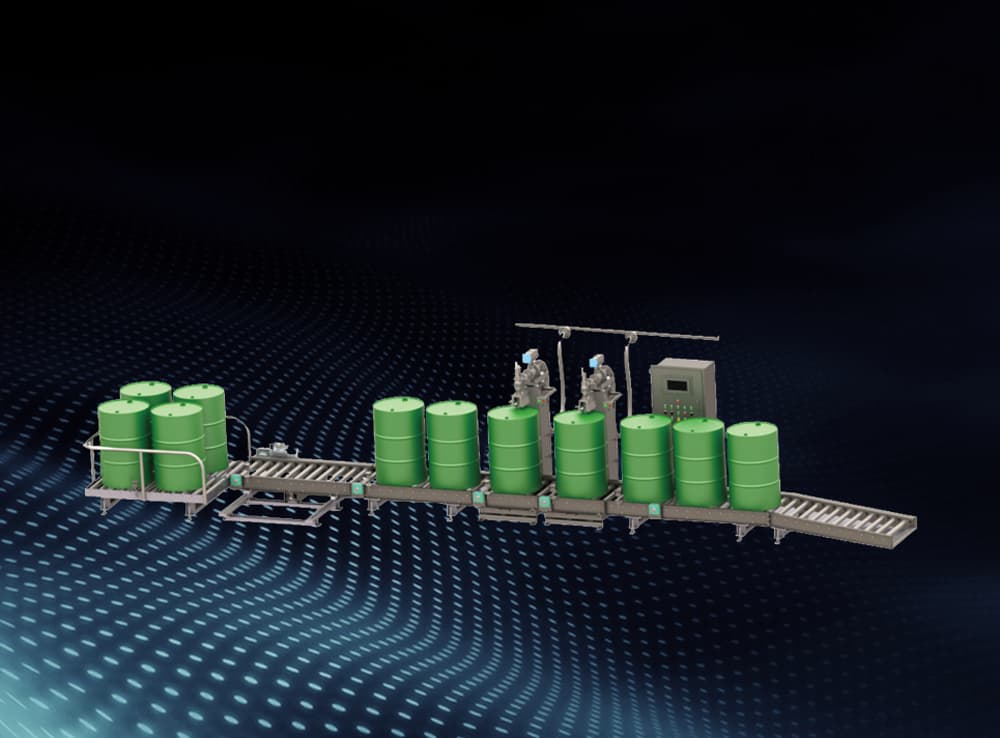

KZ-DCS-300 series weighing liquid filling machine can be used in conjunction with marking machines, coding machines, labeling machines, capping machines, capping machines, conveyors and other supporting equipment to form automatic and semi-automatic filling production lines according to different materials and process requirements.

Qualification