- Agriculture / Food

- Apparel / Textiles / Accessories

- Auto / Transportation

- Bags / Shoes / Accessories

- Electronics

- Electrical Equipment / Components / Telecoms

- Gifts / Sports / Toys

- Health / Beauty

- Home / Lights / Construction

- Machinery / Industrial Parts / Tools

- Metallurgy / Chemicals / Rubber / Plastics

- Packaging / Advertising / Office

Non-standard automated equipment

-

MPO needle loading machine

The needle has a diameter of 0.65mm, with a 0.2-slot camera at one end. It is divided into front and rear heads. The support body and the needle vibration disc feed materials. The assembly accuracy is ±0.02mm. The thickness of the support body is 0.2mm. After assembly, the support body must not deform, and the straightness requirement is within 0.02mm

2. Assembly efficiency :25 pieces per minute -

Wine box label peeling and labeling machine

1. The incoming materials of the label are bulk materials. The conventional vibrating disc feeding and holding materials, 3M tape sticking and material jamming, the equipment adopts a reciprocating feeding label method to solve the material jamming problem. The film removal is carried out by the air knife separation method, combined with the positioning of the mechanical hand camera for film removal and labeling

2. Efficiency :25 per minute -

Punching and riveting equipment

1. Rivets are fed by the push plate machine. For larger body brackets, a chain plate machine is used in combination with direct vibration screening for feeding. After assembly is completed, the rivets are sent to the bottom of the press through a divider for stamping and riveting, and are automatically discharged

2. Efficiency :20 per minute -

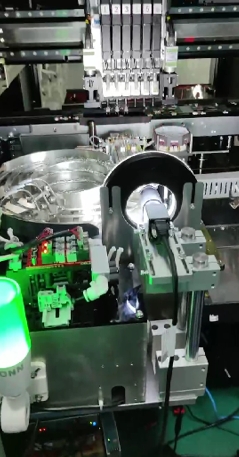

Instrument tube printing equipment

Transparent instrument tube printing, 6 products are printed simultaneously. The printing is rotated 120° to print on three surfaces. After printing, it is dried. Printing requirements: no broken lines, false printing, burrs or other abnormalities should be observed under a microscope

2. Efficiency :40 per minute -

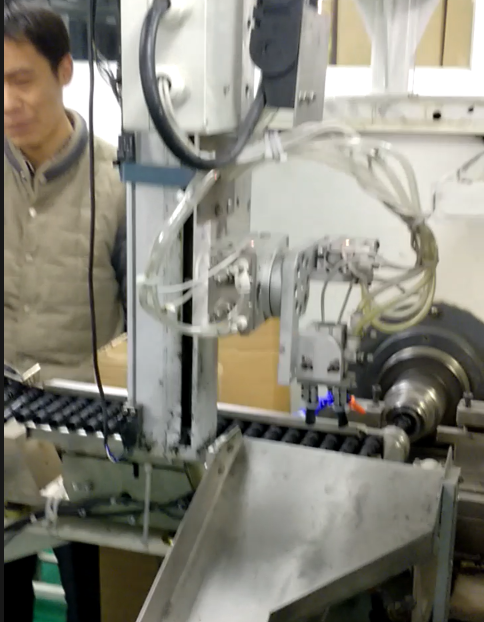

Robot punch press loading and unloading equipment

The stamping products are separated by a separator. The robot takes the materials and places them into the stamping machine fixture. After stamping, the products are transported by the robot to the next process for assembly or blanking

2. Efficiency :10 per minute -

Pin insertion machine equipment

1. Needle insertion machines such as standard needles, round needles, S-shaped needles, and fisheye needles are used. The needles are fed through the vibrating disc, and the insertion machine takes the materials and inserts the needles. They are highly efficient and stable. The insertion machines using standard machines and component insertion machines have strong versatility. In the later stage, the equipment can be changed to surface mount or through-hole, etc

2. Efficiency :60 per minute