- Agriculture / Food

- Apparel / Textiles / Accessories

- Auto / Transportation

- Bags / Shoes / Accessories

- Electronics

- Electrical Equipment / Components / Telecoms

- Gifts / Sports / Toys

- Health / Beauty

- Home / Lights / Construction

- Machinery / Industrial Parts / Tools

- Metallurgy / Chemicals / Rubber / Plastics

- Packaging / Advertising / Office

Granulator

-

160 swing granulator

The swing granulator is mainly used to manufacture various specifications of granules in the pharmaceutical, chemical, food and other industries. After drying, it can be used to press various shaped products. The machine can also be used to crush the condensed dry materials. The material contact points are made of stainless steel, with beautiful appearance, convenient cleaning, simple operation and low energy consumption.

-

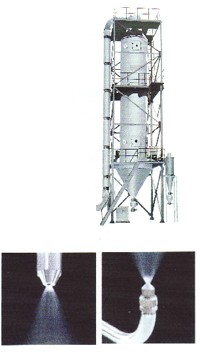

Boiling granulator (one-step boiling granulator)

The principle of the boiling granulation dryer is that the material powder particles are in an annular fluidized state in the raw material container (fluidized bed). They are preheated and mixed by the purified heated air, and the adhesive solution is atomized and sprayed, so that a number of particles gather into agglomerates containing adhesive. Due to the continuous drying of the hot air on the material, the moisture in the agglomerates evaporates, and the adhesive solidifies. This process is repeated.

-

Rotary Granulator

The rotary granulator is mainly used in pharmaceutical, food, granule, chemical, solid beverage and other industries to make the stirred materials into the required particles, especially for materials with high viscosity. All parts in contact with materials of this machine are made of stainless steel, with beautiful appearance, reasonable structure, high granulation forming rate, beautiful particles, automatic discharge, avoiding particle damage caused by manual discharge, and suitable for flow operation.

-

FL boiling granulator (one-step granulator)

Application Overview

▲The boiling granulator is mainly used for mixing, granulating and drying powder materials in the industries of medicine, food and chemical industry. Particle "top spray" coating and other operations. Such as tablet granules, instant drinks. Granules for condiments.

▲This machine is designed and manufactured according to JB20014-2004 (medicinal boiling granulator) standard. -

YK-160 wet granulator

Features

▲YK-160 wet granulator is a new generation of granulation and granulation equipment developed by our factory with reference to similar foreign models and combined with the characteristics of domestic pharmaceutical companies. Compared with the ordinary domestic swing pellet machine, it has the advantages of small footprint, compact and simple machine structure design, simple and convenient operation and maintenance of equipment, easy disassembly and cleaning, no dead angle, etc., and meets GMP requirements. This machine is mainly composed of the swing roller part, the body part, the transmission part, the tightening device and so on.

▲The transmission part of YK160 wet granulator

▲YK160 Trolley Granulator

▲This machine is combined with GHL series (high-efficiency wet granulator) and FL (PGL) series (boiling granulation dryer) to form a pipeline production, reduce secondary pollution, and have high production efficiency. -

JZL rotary granulator

Purpose overview

▲This machine injects the wet material produced by the previous process into the stainless steel screen cylinder sieve hole of the ring mill through a set of rotating milling knives, so as to make cylindrical wet particles for the next process of shot blasting. This equipment can obtain particles of different sizes by replacing the stainless steel sieve cylinder.

▲Humidification particles can also be based on the material and the size of the required spherical particles.