- Agriculture / Food

- Apparel / Textiles / Accessories

- Auto / Transportation

- Bags / Shoes / Accessories

- Electronics

- Electrical Equipment / Components / Telecoms

- Gifts / Sports / Toys

- Health / Beauty

- Home / Lights / Construction

- Machinery / Industrial Parts / Tools

- Metallurgy / Chemicals / Rubber / Plastics

- Packaging / Advertising / Office

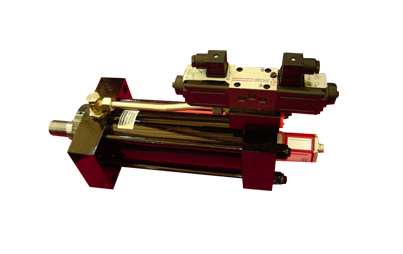

Oil Cylinder

-

Multi section oil cylinder

Analysis on fault diagnosis and maintenance of hydraulic cylinder hydraulic cylinder is the actuating element that converts hydraulic energy into mechanical energy in hydraulic system. Its faults can be basically summarized as hydraulic cylinder misoperation, inability to push load, piston sliding or creeping, etc. The initial action of the hydraulic cylinder is slow. In the case of low temperature, the hydraulic oil has high viscosity and poor fluidity, which causes the hydraulic cylinder to move slowly. The improvement method is to replace the hydraulic oil with good viscosity temperature performance. Under low temperature, the oil temperature during startup can be improved by using a heater or using the machine itself to heat.

-

Non standard customized oil cylinder

Five basic points for oil cylinder maintenance

1. Keep the oil clean, because the dirt in the oil will damage the parts of the system;

2. Keep the oil volume. If the oil is less, the non-standard cylinder barrel company will enter air, which will cause abnormal operation of the hydraulic cylinder system;

3. The non-standard cylinder barrel factory should pay attention to the oil leakage. The oil leakage indicates that there is a problem with the seal and it should be replaced in time. In this case, not only the oil is consumed, but also the power is reduced, and the system operation is seriously stopped;

4. Be familiar with the sound of hydraulic system operation. The sound of normal operation is different from that of abnormal operation. If you hear abnormal sound, it means that there is a fault. Scan it in time to avoid small problems becoming big damage and causing big impact;

5. Pay attention to check whether the fasteners are loose, and keep checking at all times to avoid loose state -

Engineering hydraulic cylinder

Structure of engineering hydraulic cylinder

The inner part of the cylinder block is divided into two parts by a piston, namely a large chamber and a small chamber; Large cavity refers to the inner cavity of the cylinder block after the piston rod is fully extended; Small cavity refers to the inner cavity of engineering hydraulic cylinder body and rod body after the piston rod is fully extended; As the viscosity of hydraulic oil is high and the compression ratio is small, when the oil enters the oil port at the bottom of the cylinder, the piston will be pushed to make the oil outlet of the cylinder head, and the piston will drive the piston rod to extend or retract, and vice versa.

The hydraulic oil cylinder is generally composed of cylinder barrel, piston rod, cylinder head, piston, seals, etc.

The cylinder barrel (TUBE) is composed of four parts: cylinder block, flange, cylinder bottom and bushing. The piston rod (ROD) is composed of three parts: 1. rod body, 2. ear ring, 3. bushing and above;

There are five basic components of stainless steel oil cylinder: cylinder barrel and head, piston and piston rod, sealing device, buffer device and exhaust device. -

Engineering oil cylinder

Advantages of using hydraulic cylinder of engineering vehicle

The hydraulic cylinder of the engineering vehicle comprises a cylinder barrel, a cylinder tail, a guide sleeve, a piston and a piston rod. The cylinder tail and guide sleeve are respectively arranged at both ends of the cylinder barrel, and the cylinder tail and guide sleeve are respectively connected with the cylinder barrel through screws. Oil holes are respectively arranged on the cylinder tail and cylinder barrel.

The cylinder wall of the cylinder barrel is embedded with a heat pipe, which is made of copper. The left end of the heat pipe passes through the cylinder tail and is connected with a radiator, which is equipped with a radiator. The hydraulic cylinder barrel of the engineering vehicle is equipped with a piston sliding, a piston seal ring is set between the piston and the inner wall of the cylinder barrel, a threaded hole is set in the piston, the piston rod is fixed on the piston through the threaded hole, and an O-ring is set between the piston rod and the piston.

The right end of the piston rod passes through the guide sleeve. An ear ring is fixed on the right end of the piston rod. A seal ring is set between the piston rod and the guide sleeve. A dust ring is fixed at the beginning of the right end of the guide sleeve, and the piston rod passes through the dust ring. A mounting channel is arranged in the piston rod. The heat sink is set with 10-15 heat sinks, which are made of aluminum, and the distance between the heat sinks is 5-1mm. The width of the piston seal ring is 3-5 mm. The diameter of the installation passage is 1/3-1/2 of the diameter of the piston rod.

The utility model is provided with a heat pipe in the cylinder wall. The heat pipe transfers the heat generated on the hydraulic cylinder barrel of the engineering vehicle to the radiator, which emits the heat, reduces the temperature of the cylinder, reduces the heat accumulation, protects the components of the cylinder, improves the safety of the hydraulic cylinder, and extends the service life of the hydraulic cylinder of the engineering vehicle. -

Sanitation oil cylinder

The hydraulic cylinder of sanitation vehicle of Wuxi oil cylinder manufacturer is a kind of hydraulic cylinder, which is used on vehicles or equipment in the sanitation industry. According to the structural form of the hydraulic cylinder of sanitation vehicle, it can be divided into three types: the hydraulic cylinder of sanitation garbage truck has various structural forms, There are also many ways to classify them: according to the motion mode, they can be divided into linear reciprocating hydraulic cylinders and rotary swinging hydraulic cylinders of sanitation vehicles; According to the action of hydraulic pressure, it can be divided into single acting hydraulic cylinder and double acting hydraulic cylinder; According to the structure, it can be divided into piston type sanitation vehicle hydraulic cylinder, plunger type sanitation vehicle hydraulic cylinder, multi-stage telescopic sleeve type sanitation vehicle hydraulic cylinder, gear rack type sanitation vehicle hydraulic cylinder, etc; According to the installation form, it can be divided into pull rod sanitation vehicle hydraulic cylinder, ear ring sanitation vehicle hydraulic cylinder, foot sanitation vehicle hydraulic cylinder, hinge axle sanitation vehicle hydraulic cylinder, etc; According to the pressure grade, it can be divided into 16Mpa sanitation vehicle hydraulic cylinder, 25Mpa sanitation vehicle hydraulic cylinder, 31.5Mpa sanitation vehicle hydraulic cylinder, etc.

-

Small oil cylinder

The hydraulic system of a hydraulic cylinder requires multiple hydraulic oil circuit boards, so the system should be properly disassembled. In consideration of many practical problems, the following two points should be noted: the hydraulic components of the hydraulic cylinder should be arranged on the same hydraulic oil circuit board, and the connecting pipes should be minimized. For automatic machine tool processing line or multi station machine tool hydraulic system, parts with the same structure shall be designed as interchangeable universal plates, and parts with different structures shall be designed as special ones. The selection of hydraulic cylinder must follow many hydraulic principles, and must not be changed at will. Use a relatively dry cleaner to clean the hydraulic cylinder, and then remove the solvent residue in the filtered air. All pipelines of the system need to be cleaned, and in some cases, pipelines and joints need to be impregnated. Oil filter shall be installed in the hydraulic cylinder pipe to protect the oil supply pipe and pressure pipe from damage. Install a flushing plate on the collector to replace the precision valve. Check whether all pipe sizes are appropriate and the connections are correct.