- Agriculture / Food

- Apparel / Textiles / Accessories

- Auto / Transportation

- Bags / Shoes / Accessories

- Electronics

- Electrical Equipment / Components / Telecoms

- Gifts / Sports / Toys

- Health / Beauty

- Home / Lights / Construction

- Machinery / Industrial Parts / Tools

- Metallurgy / Chemicals / Rubber / Plastics

- Packaging / Advertising / Office

Insulating Powder

-

CM260 High-Temperature Fast Solidification Powder

Performance characteristics

CM260 high-temperature fast solidifying powder is developed using various composite curing agents, toughening agents, and high-quality solid oxygen reducing resins, in contrast to the technical indicators of similar foreign products

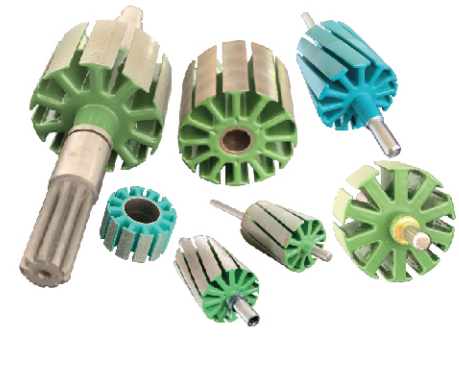

It has bright colors, good electrical performance, moisture resistance, rapid curing performance, good corner coverage, and excellent shear penetration resistance; At the same time, it has the advantages of reducing electrode temperature rise, increasing slot capacity, simplifying winding process, ensuring product quality, improving production efficiency, and achieving mechanical assembly line operation. It is widely used for various types of small DC motors, motor rotors, iron core slots, and end insulation coating.

Coating process

Adopting electrostatic fluidized bed thermal coating method and high-frequency automatic rapid coating method.

Packaging and storage

Packaged in high-quality round paper drums. 25KG per barrel -

CM260K Magnetic Ring Special Flame Retardant Insulation Powder

Performance characteristics

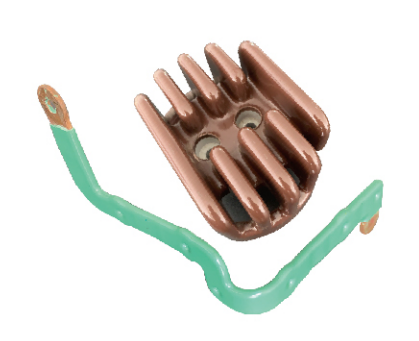

CM260K magnetic ring special insulation powder is a high-quality raw material that our company uses according to market demand, such as special epoxy, curing agent, nano modifier, etc., through hot melting and powder insulating powder made by crushing and magnetic separation. This powder has an ultra-fast curing speed and excellent mechanical and electrical strength

Purpose

Mainly used for matrix insulation of various magnetic rings.

Coating process

This product is coated using a rotary vibration automatic coating machine

Product Certification

The product has passed UL certification in the United States and meets the requirements of the EU RoHS environmental protection directive; Simultaneously passing SVHC high concern substance detection.

Packing

Packaged in high-quality round paper drums or cardboard boxes lined with high-pressure polyethylene bags. The shelf life under low-temperature ventilation conditions is 3 months -

CM260P High-Temperature Fast Solidification Powder

Performance characteristics

It has bright colors, excellent electrical performance, moisture resistance, rapid curing performance, excellent resistance to cold and hot deformation, cutting penetration, and good edge coverage. At the same time, it has the advantages of reducing motor temperature rise, increasing slot capacity, simplifying winding process, ensuring product quality, improving production efficiency, and achieving mechanical assembly line operation.

Purpose

Insulation coating for various DC motors, motors, magnetos, and other rotors, iron core slots, and iron core ends.

Coating process

Using electrostatic fluidized bed coating method and high-frequency automatic rapid coating method.

Product Certification

The product has passed UL certification in the United States and meets the requirements of the EU RoHS environmental directive; Through SVHC high concern substance detection.

Packing

Packaged in high-quality round paper tubes, lined with high-pressure polyethylene bags. 25 kilograms per barrel. Indoor storage, ventilated and dry. -

CM260B Coil Specific Insulation Powder

Performance characteristics

CM260B coil specific insulation powder is a special type of insulation powder designed specifically for the fixation and insulation of electric tool stator and rotor, motor, and automotive motor coils. It is made of high-purity epoxy, microcapsule encapsulated curing agent, toughening agent, and other materials through hot melting, crushing, grading, and magnetic separation. This powder has strong line and circle permeability and mechanical resistance. Suitable for fixing and insulation of coil windings. It is an ideal product to replace binding, paint dripping, energy conservation and environmental protection. It has been replaced by many electric tool enterprises such as Nantong, Yongkang, Shenzhen, and other similar imported products.

Packaging and storage

Packaged in high-quality round paper drums, lined with high-pressure polyethylene bags. 25 kilograms per barrel. Indoor storage, ventilated and dry -

CM260X High Toughness Insulation Powder

Performance characteristics

CM260X is a new type of insulation powder made by our company based on market demand, using materials such as nano modified epoxy, high-quality curing agent, toughening agent, etc. through hot melting, crushing, and magnetic separation. This powder has super strong flexibility and bending strength. Suitable for surface insulation of electrical workpieces with high requirements for flexibility. Especially recommended for electrode encapsulation insulation of automotive starting motors. Compared with traditional binding and painting processes, using powder coating technology can save more than 90% of labor and over 30% of energy.

Coating process

Use fluidized bed immersion coating or electrostatic spraying method

Packaging and storage

Packaged in high-quality round paper drums, lined with high-pressure polyethylene bags. 25 kilograms per barrel. Indoor storage, ventilated and dry. -

CM260H High-Temperature Fast Solidification Powder

Performance characteristics

It has bright colors, excellent electrical performance, moisture resistance, rapid curing performance, excellent resistance to cold and hot deformation, cutting penetration, good edge coverage, and the advantages of reducing motor temperature rise, increasing slot capacity, simplifying winding process to ensure product quality, improving production efficiency, and achieving mechanical assembly line operation

Purpose

Insulation coating for various DC motors, motors, magnetos, and other rotors, iron core slots, and iron core ends.

Coating process

Using electrostatic fluidized bed coating method and high-frequency automatic rapid coating method.

Product Certification

The product has passed UL certification in the United States and meets the requirements of the EU RoHS environmental protection directive; Through SVHC high concern substance detection.

Packing

Packaged in high-quality round paper tubes, lined with high-pressure polyethylene bags. 25 kilograms per barrel. Indoor storage, ventilated and dry. -

CM260E High-Temperature Fast Curing Insulation Powder

Performance characteristics

Our company selects high-purity solid epoxy resin and special composite curing agent based on the actual situation in our country, which is made through processes such as hot mixing, crushing, magnetic separation, etc. Compared with ordinary insulation powder, it has better heat resistance and thermal shock resistance, and the coating is smooth, high-density, and has good electrical strength.

Purpose

Insulation coating for rotors, iron core slots, and iron core ends of DC motors and motors with temperature resistance requirements.

Recommended coating process

Electrostatic fluidized bed method/thermal spraying method/immersion coating method

Product Certification

Complies with EU RoHS environmental directive requirements and UL certification.

Packaging/Storage

Packaged in high-quality paper drums (boxes), with a storage period of 3-6 months at room temperature, dry, and ventilated conditions. -

CZ1531-2 Decahydrazine Elastic Insulation Powder

Performance characteristics

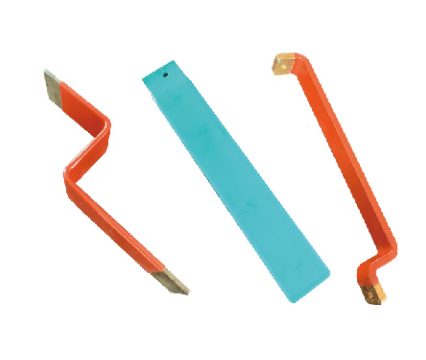

Decahydrazine elastic insulation powder is developed based on the insulation coating of domestic electrical switch busbars and related accessories, which has good bending performance, electrical performance, moisture-proof performance, and anti-corrosion performance. Widely used for surface insulation coating of copper, aluminum bars, electrical accessories, magnetic pole coils, and other work on switch busbars. Gui bullet powder is a functional epoxy resin powder coating made from high-quality epoxy resin, curing agent, toughening agent, and other materials through hot melt mixing, crushing, screening, and magnetic separation. Complies with EU RoHS environmental indicators.

Coating process

The coating method adopts electrostatic fluidized bed or fluidized bed immersion coating.

Packaging and storage

Packed in high-quality round paper drums, each weighing 25KG. Room temperature, dry, and ventilated storage period of 12 months -

FZJ-308A Flame-Retardant Elastic Insulation Powder

Performance characteristics

Flame retardant insulation powder is developed by our company's technical personnel and experts from Guangzhou Institute of Science and Technology, comparing the technical indicators of advanced foreign products and selecting high-quality imported epoxy resin, toughening agent, and curing agent. Its main technical indicators have reached or exceeded similar foreign products. The coating is uniform, the surface is flat, and there are multiple colors, with good electrical, moisture-proof, bending performance, and unique flame retardant performance. It can reduce the distance between phases and ground, reduce the volume of the cabinet, save energy, improve production efficiency, and achieve mechanical assembly line operation. Widely used for external insulation coating of electrical components such as dry switch busbars, aluminum bars, short circuiters, insulated pull rods, coils, etc.

Coating process

Use electrostatic fluidized bed coating method or fluidized bed immersion coating method.

Packaging and storage

Packed in high-quality round paper drums, each weighing 25KG. The storage period at room temperature, dry, and ventilated is 12 months. -

FZJ-308 Flame-Retardant Elastic Insulation Powder

Performance characteristics

Flame retardant insulation powder is developed by our company's technical personnel and experts from Guangzhou Institute of Science and Technology, comparing the technical indicators of advanced foreign products and selecting high-quality imported epoxy resin, toughening agent, and curing agent. Its main technical indicators have reached or exceeded similar foreign products. The coating is uniform, the surface is flat, and there are multiple colors, with good electrical, moisture-proof, bending performance, and unique flame retardant performance. It can reduce the distance between phases and ground, reduce the volume of the cabinet, save energy, improve production efficiency, and achieve mechanical assembly line operation. It is widely used for external insulation coating of electrical components such as dry switch busbars, aluminum bars, short circuiters, insulation pull rods, coils, etc.

Coating process

Use electrostatic fluidized bed coating method or fluidized bed immersion coating method.

Packaging and storage

Packed in high-quality round paper drums, each weighing 25KG. The storage period at room temperature, dry, and ventilated is 12 months. -

CM260C Flame-Retardant Epoxy Powder Encapsulation Material

Performance characteristics

Flame retardant insulation powder is developed by our company's technical personnel and experts from Guangzhou Institute of Science and Technology, comparing the technical indicators of advanced foreign products and selecting high-quality imported epoxy resin, toughening agent, and curing agent. Its main technical indicators have reached or exceeded similar foreign products. The coating is uniform, the surface is flat, and there are multiple colors, with good electrical, moisture-proof, bending performance, and unique flame retardant performance. It can reduce the distance between phases and ground, reduce the volume of the cabinet, save energy, improve production efficiency, and achieve mechanical assembly line operation. It is widely used for external insulation coating of electrical components such as dry switch busbars, aluminum bars, short circuiters, insulation pull rods, coils, etc.

Coating process

Use electrostatic fluidized bed coating method or fluidized bed immersion coating method.

Packaging and storage

Packed in high-quality round paper drums, each weighing 25KG. The storage period at room temperature, dry, and ventilated is 12 months.