- Agriculture / Food

- Apparel / Textiles / Accessories

- Auto / Transportation

- Bags / Shoes / Accessories

- Electronics

- Electrical Equipment / Components / Telecoms

- Gifts / Sports / Toys

- Health / Beauty

- Home / Lights / Construction

- Machinery / Industrial Parts / Tools

- Metallurgy / Chemicals / Rubber / Plastics

- Packaging / Advertising / Office

Intelligent kitchen and kitchen equipment

-

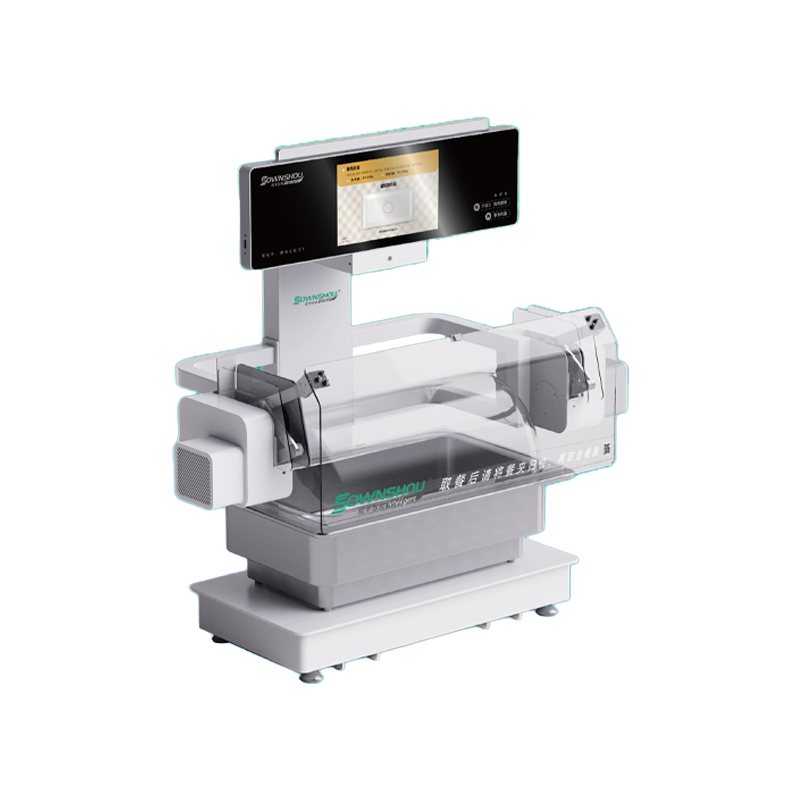

Intelligent self-service weighing and cashier system

Weighing sensor

Self-service meal pickup on demand

"One dish, one price; let people choose according to their budget, greatly enhancing the dining experience."

Touch screen display

Customer consumption visualization

Direct push of consumption data

Fall protection

Industry-leading patent

Intelligent landing protective cover, automatically rises and falls

Preventing droplets is more hygienic

It's safer to prevent vegetable theft

automatic pricing

Compatible with industry-unique member and non-member scenarios

Technical support for quick payment methods such as face recognition, card swiping, or mobile phone scanning

The settlement speed can reach the second level

Effectively avoid the problem of queuing for settlement

Real-time data analysis

Real-time data such as dish sales rankings

Assist in customer sentiment analysis and optimization

The operation report is clear and concise -

Smart Fryer (SF10 Standard Version, SF10 Pro Oil Fume Purification Version)

Operational standardization

The unlimited menu technology library provides the production techniques of various dish categories wirelessly through the Saas system

Fully compatible with all cooking appliances

The portion sizes of processed dishes range from small, such as home-cooked dishes weighing around 500 grams per serving, to large, such as fast food canteen dishes weighing around ten pounds

Exhaust fume treatment system

The robot comes with a built-in exhaust fume treatment system, eliminating the need for additional exhaust pipes. The machine directly converts the fumes into a liquid

Smart spice jar function

Equipped with eight seasoning cans, it supplies independent and compound seasonings used in the processing of various dishes. At the same time, each seasoning can is equipped with a shortage alarm function to avoid the loss of taste in processed dishes caused by unawareness of shortage during processing

Multimodal machining system

Scanning the code automatically starts cooking, and the feeding system offers multiple modes: manual feeding, on-site pre-preparation and automatic feeding mode, and centralized workshop production and automatic feeding mode using material boxes

Precise temperature control and protection

The cooking pot of the stir-fry machine is equipped with a temperature control function, which prevents the pot from being burned due to uncontrolled heat caused by inconsistent cooking time when the dish has different volumes

Stable operation offline

The machine is equipped with an offline mode, ensuring normal operation even in environments with unstable network connections -

Universal steam oven (four trays, six trays, ten trays)

Core control system

Independently developed control system, OEM from major manufacturers, stable and reliable performance, strong flexibility.

The Mitsubishi variable speed system controls the forward and reverse rotation of the stepless variable speed fan.

Italian brand Zopas heating tube

6-point core temperature probe, precisely controlling cooking temperature

High-end materials and structure

Overall stretching of the stainless steel 304 inner chamber

Three-layer high-quality tempered glass security door, heat-resistant and anti-vandal

High-brightness LED light strip, bright and durable

Intelligent interactive interface

10.1-inch "Zhongke Shiwei" high-stability capacitive screen

Data management and remote control

IOT remote data acquisition function

Automatic backup of memory data, meeting HACCP requirements

USB interface, facilitating menu and program updates

Innovation in cooking functions

Pan rack timing and layered baking function

SaaS system platform, with unlimited menu expansion capacity and equipped with a dehumidification valve

Reliability Verification

All components have undergone aging tests, ensuring they are durable and long-lasting

Convenient maintenance

With automatic cleaning function -

Integrated fully automatic intelligent cooking machine

Mandatory standardized weighing function module

According to the menu process, the dish preparation staff is required to weigh the ingredients

Synchronize the ingredient preparation status in real-time with the cooking machine

Avoid the situation where the taste of the finished product is not standardized due to differences in the amount of raw materials and the process

Storage cabinet automatic identification and storage function module

Automatically identify the weight and shape standards for garnish preparation techniques to ensure consistent implementation of dish craftsmanship.

Prepare ingredients for the cooking system

Robot arm automatic feeding function module

Intelligentized material searching in storage cabinets

Automatically dispense raw materials according to the process

Fully intelligent cooking machine

Automatically control the heat according to the cooking process of the dish

Automatically control the stir-frying frequency according to the dish's cooking process, and automatically add liquid or solid seasoning according to the dish's cooking process

Through unified research and development control of menus, remote menu process delivery and management, we provide professional chef-level research and development support for various dishes for projects without chefs

Industry-leading feature: Natural attenuation caused by the service life of equipment is addressed through the system's self-checking process compensation function, ensuring continuous standardized use of menu processes

Powerful dish library function

It has a vast private library and public library

The unlimited expansion of the dish craft library brings convenience to various smart canteens and intelligent restaurants in achieving chef-less operations

High compatibility with single serving capacity

1-50 jin, meeting the meal delivery needs of various projects

Ultra-broad applicable scenarios

Canteens, fast food restaurants, enterprises, institutions, hospitals, schools, factories, industrial parks, communities

cost reduction and efficiency improvement

Without relying on chefs, labor costs can be saved by 30%-50% -

Receiving and inspection inventory control system

The intelligent inbound and outbound scale is an electronic scale that integrates weighing, data collection, processing, and management functions. It can transmit weighing data to the back-end system in real time and enable functions such as data analysis, management, and monitoring. It is primarily used for managing the inbound and outbound of items and inventory management.

Quick query

Input the product name in the search box to query various information about the product with one click.

Data processing

The built-in computer processes data, recording information such as the quantity, weight, unit price, and total price of items.

Inventory Management

By identifying information such as barcodes of items, automatic identification and classification of items can be achieved, reducing manual operations and errors.

Precise measurement

Accurately measure the item according to the preset measurement unit, and display the measurement result on the digital display screen. -

Intelligent sample retention system

The food sample storage cabinet is a specialized device used to store daily food samples prepared in the cafeteria. By preserving these samples at low temperatures for a certain period of time, it allows for traceability and testing in case of food safety issues. This device supports compartmentalized management, allowing different types of food samples to be stored separately to avoid cross-contamination, while also facilitating easy retrieval and management.

Grid management

Support compartmentalized management, allowing for separate storage of different types of food samples, facilitating management and retrieval.

Diverse recognition

Supports multiple personnel identification methods, including face recognition, card swiping, and QR code scanning.

Temperature control

The temperature inside the cabinet is maintained between 0-10°C to ensure the freshness and safety of the food samples retained.

High Efficiency and Energy Saving

The food sample cabinet adopts efficient refrigeration technology and energy-saving design, which can reduce energy consumption while ensuring the quality of food storage.