- Agriculture / Food

- Apparel / Textiles / Accessories

- Auto / Transportation

- Bags / Shoes / Accessories

- Electronics

- Electrical Equipment / Components / Telecoms

- Gifts / Sports / Toys

- Health / Beauty

- Home / Lights / Construction

- Machinery / Industrial Parts / Tools

- Metallurgy / Chemicals / Rubber / Plastics

- Packaging / Advertising / Office

Casting

-

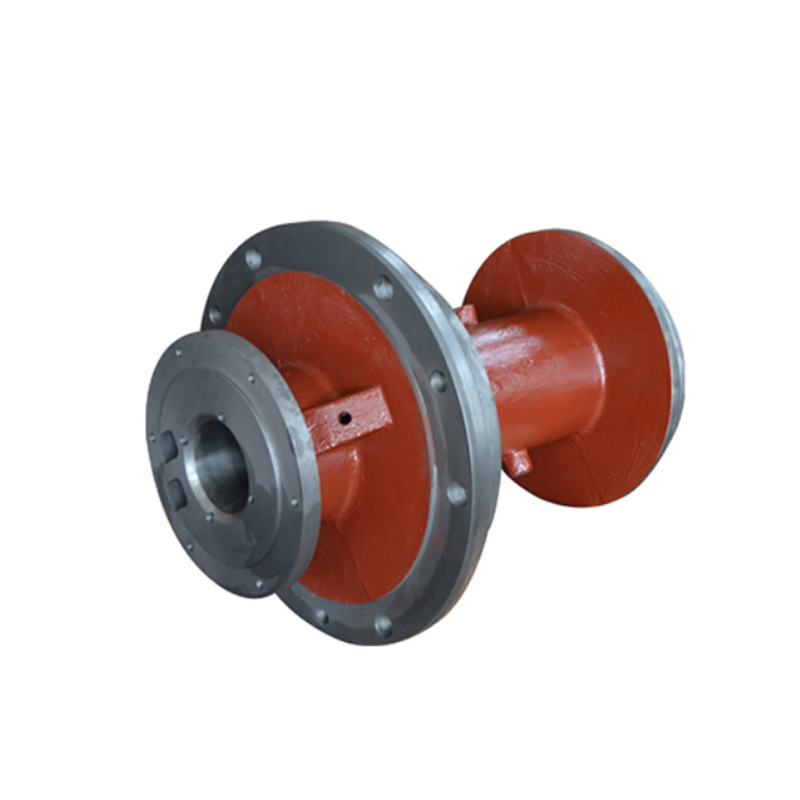

Export flywheel

Export flywheel

The flywheel, a disk-shaped part with a large moment of inertia, acts like an energy store. For a four-stroke engine, work is done once every four piston strokes, that is, only the work stroke is done, while the exhaust, intake and compression strokes all consume work. Therefore, the torque output to the external crankshaft changes periodically, and the crankshaft speed is also unstable. To improve this situation, a flywheel is installed at the rear end of the crankshaft.

function

At the power take-off end of the crankshaft, that is, the side that connects the gearbox and the work equipment. The main function of the flywheel is to store energy and inertia outside the power stroke of the engine. A four-stroke engine only does work in one stroke, and the energy for suction, compression and exhaust comes from the energy stored by the flywheel. The balance is corrected wrong, the balance of the engine mainly depends on the balance block on the shaft, the single-cylinder engine has a balance shaft.

The flywheel has a large moment of inertia. Since the work of each cylinder of the engine is not continuous, the engine speed also changes. When the engine speed increases, the kinetic energy of the flywheel increases, storing energy; When the engine speed decreases, the flywheel kinetic energy decreases, releasing energy. The flywheel can be used to reduce speed fluctuations during -

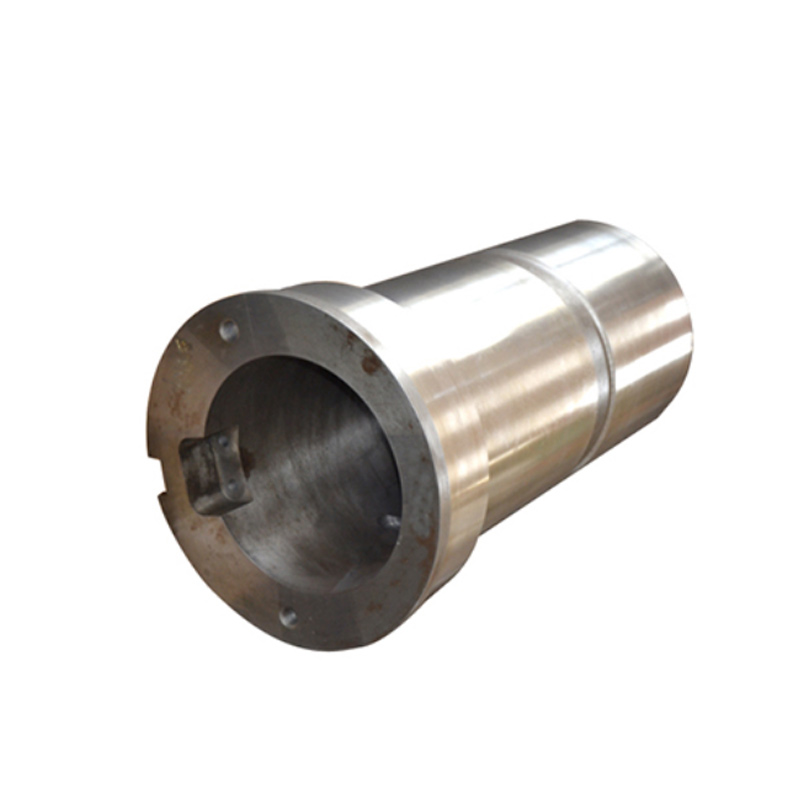

Drive shaft mount

Drive shaft mount

The propeller shaft is a rotating body with high speed and low support, so its dynamic balance is crucial. Generally, the drive shaft is subjected to a dynamic balance test before leaving the factory, and adjusted on the balancing machine. For the front-engine, rear-wheel drive car, the rotation of the transmission is transmitted to the shaft of the main reducer, which can be several sections, and the joints can be connected by universal joints.

function

The propeller shaft is an important component of the transmission power in the drive train of the car, and its function is to transmit the power of the engine to the wheels together with the gearbox and drive axle, so that the car produces driving force.

use

Special automobile drive shafts are mainly used in tank trucks, fuel trucks, sprinkler trucks, sewage suction trucks, fecal suction trucks, fire trucks, high-pressure cleaning trucks, road wreckers, aerial work vehicles, garbage trucks and other models.

structure

The propeller shaft is composed of shaft tube, telescopic sleeve and universal joint. The telescopic sleeve automatically adjusts the change in the distance between the transmission and the transaxle. The universal joint is to ensure the change of the angle between the two axes of the transmission output shaft and the input shaft of the drive axle, and realize the isometric transmission of the two shafts. -

Eccentric seat

Drive shaft mount

The propeller shaft is a rotating body with high speed and low support, so its dynamic balance is crucial. Generally, the drive shaft is subjected to a dynamic balance test before leaving the factory, and adjusted on the balancing machine. For the front-engine, rear-wheel drive car, the rotation of the transmission is transmitted to the shaft of the main reducer, which can be several sections, and the joints can be connected by universal joints.

function

The propeller shaft is an important component of the transmission power in the drive train of the car, and its function is to transmit the power of the engine to the wheels together with the gearbox and drive axle, so that the car produces driving force.

use

Special automobile drive shafts are mainly used in tank trucks, fuel trucks, sprinkler trucks, sewage suction trucks, fecal suction trucks, fire trucks, high-pressure cleaning trucks, road wreckers, aerial work vehicles, garbage trucks and other models.

structure

The propeller shaft is composed of shaft tube, telescopic sleeve and universal joint. The telescopic sleeve automatically adjusts the change in the distance between the transmission and the transaxle. The universal joint is to ensure the change of the angle between the two axes of the transmission output shaft and the input shaft of the drive axle, and realize the isometric transmission of the two shafts. -

Gray iron casting

The basic characteristics of gray iron castings are: high clay content, low moisture, and low amount of pulverized coal.

The basic feature of high density molding sand for gray iron castings is that the amount of pulverized coal added is also low. Therefore, the following points should be grasped during sand mixing.

① Clay content and mud content. The strength of molding sand with high clay content also increases with the increase of specific pressure, and the effective bentonite is usually controlled at 7%~10%. The sum of effective clay and dead clay in molding sand is equivalent to the mud content

The mud volume is generally controlled at 12%~16%. If the mud content is too high or too low, all performance indexes of molding sand will be affected.

② Moisture. The water content in the sand produced by lost foam casting is the main factor that determines the plasticity and adhesion of clay. When the water content is too high, it is easy to bow | stick t, the binding force deteriorates, the fluidity of molding sand decreases, and the uniformity of molding sand is not obtained

Mold density. When the water content is too low, the molding sand is not easy to mix, the strength of the molding sand is low, the brittleness is large, and the mold liftoff is poor, which is easy to cause the sand sticking defect of the casting. Generally, the moisture content shall be controlled at 10% higher than the moisture content at the peak value of wet compression strength

③ Original sand grain size. The density of sand mold is high during high-density molding and the expansion is large during pouring. Therefore, the original sand size should not be too concentrated. The original sand particles are circular or polygonal. Generally, three-screen sand or four-screen sand is selected. -

Ductile iron castings

Ductile iron casting is a kind of high-strength cast iron material, its comprehensive properties are close to steel. It can effectively improve the mechanical properties of cast iron, especially the plasticity and toughness. Due to its excellent performance, it is used for casting some stresses

Complex, high strength, good toughness and wear-resistant parts. It has been widely used.

Pressure pipes and pipe fittings: Since ductile iron castings can exceed the pressure resistance of ordinary cast iron pipes during transportation and are convenient for construction, it is very difficult to choose them as production materials for ductile iron castings and pipe fittings

Wrong.

Automobile technology application: ductile iron castings can be mainly used in the mechanical part of China's automobile development industry.

Agricultural machinery and construction applications: generally, agricultural machinery needs a relatively long life, and the formation of various components of ductile iron castings can only achieve this. In addition, -- some construction operations or road laying to the use of bulldozers, lifting

Ductile iron castings are also available for machinery. -

Casting

The quality inspection results of castings are generally divided into three categories: qualified products, reworked products and scrap products.

1) Qualified products refer to castings whose appearance quality and internal quality meet relevant standards or technical conditions for delivery and acceptance;

2) Reworked products refer to castings whose appearance quality and internal quality do not fully meet the standards and acceptance conditions, but are allowed to be repaired, and can meet the requirements of the standards and technical conditions for delivery and acceptance of castings after repair;

3) Waste products refer to castings that are unqualified in appearance and internal quality, and are not allowed to be repaired or still fail to meet the requirements of standards and technical conditions for delivery and acceptance after repair. Waste products are divided into internal waste and external waste. Internal disused finger

Waste castings found in the foundry or foundry; External waste refers to the waste products found after the delivery of castings, which cause much greater economic losses than internal waste.

The theory of casting forming is often called casting, and the technology of casting forming has a long history. As early as 5000 years ago, our ancestors were able to cast red copper and bronze products. Casting is a widely used gold

It belongs to wave forming process. It is a method of pouring liquid metal into the mold cavity and obtaining a certain shape of blank or part after its solidification. -

casting

The quality inspection results of castings are generally divided into three categories: qualified products, reworked products and scrap products.

1) Qualified products refer to castings whose appearance quality and internal quality meet relevant standards or technical conditions for delivery and acceptance;

2) Reworked products refer to castings whose appearance quality and internal quality do not fully meet the standards and acceptance conditions, but are allowed to be repaired, and can meet the requirements of the standards and technical conditions for delivery and acceptance of castings after repair;

3) Waste products refer to castings that are unqualified in appearance and internal quality, and are not allowed to be repaired or still fail to meet the requirements of standards and technical conditions for delivery and acceptance after repair. Waste products are divided into internal waste and external waste. Internal disused finger

Waste castings found in the foundry or foundry; External waste refers to the waste products found after the delivery of castings, which cause much greater economic losses than internal waste.

The theory of casting forming is often called casting, and the technology of casting forming has a long history. As early as 5000 years ago, our ancestors were able to cast red copper and bronze products. Casting is a widely used gold

It belongs to wave forming process. It is a method of pouring liquid metal into the mold cavity and obtaining a certain shape of blank or part after its solidification. -

Casting

The quality inspection results of castings are generally divided into three categories: qualified products, reworked products and scrap products.

1) Qualified products refer to castings whose appearance quality and internal quality meet relevant standards or technical conditions for delivery and acceptance;

2) Reworked products refer to castings whose appearance quality and internal quality do not fully meet the standards and acceptance conditions, but are allowed to be repaired, and can meet the requirements of the standards and technical conditions for delivery and acceptance of castings after repair;

3) Waste products refer to castings that are unqualified in appearance and internal quality, and are not allowed to be repaired or still fail to meet the requirements of standards and technical conditions for delivery and acceptance after repair. Waste products are divided into internal waste and external waste. Internal disused finger

Waste castings found in the foundry or foundry; External waste refers to the waste products found after the delivery of castings, which cause much greater economic losses than internal waste.

The theory of casting forming is often called casting, and the technology of casting forming has a long history. As early as 5000 years ago, our ancestors were able to cast red copper and bronze products. Casting is a widely used gold

It belongs to wave forming process. It is a method of pouring liquid metal into the mold cavity and obtaining a certain shape of blank or part after its solidification. -

Casting

The quality inspection results of castings are generally divided into three categories: qualified products, reworked products and scrap products.

1) Qualified products refer to castings whose appearance quality and internal quality meet relevant standards or technical conditions for delivery and acceptance;

2) Reworked products refer to castings whose appearance quality and internal quality do not fully meet the standards and acceptance conditions, but are allowed to be repaired, and can meet the requirements of the standards and technical conditions for delivery and acceptance of castings after repair;

3) Waste products refer to castings that are unqualified in appearance and internal quality, and are not allowed to be repaired or still fail to meet the requirements of standards and technical conditions for delivery and acceptance after repair. Waste products are divided into internal waste and external waste. Internal disused finger

Waste castings found in the foundry or foundry; External waste refers to the waste products found after the delivery of castings, which cause much greater economic losses than internal waste.

The theory of casting forming is often called casting, and the technology of casting forming has a long history. As early as 5000 years ago, our ancestors were able to cast red copper and bronze products. Casting is a widely used gold

It belongs to wave forming process. It is a method of pouring liquid metal into the mold cavity and obtaining a certain shape of blank or part after its solidification. -

Casting

The quality inspection results of castings are generally divided into three categories: qualified products, reworked products and scrap products.

1) Qualified products refer to castings whose appearance quality and internal quality meet relevant standards or technical conditions for delivery and acceptance;

2) Reworked products refer to castings whose appearance quality and internal quality do not fully meet the standards and acceptance conditions, but are allowed to be repaired, and can meet the requirements of the standards and technical conditions for delivery and acceptance of castings after repair;

3) Waste products refer to castings that are unqualified in appearance and internal quality, and are not allowed to be repaired or still fail to meet the requirements of standards and technical conditions for delivery and acceptance after repair. Waste products are divided into internal waste and external waste. Internal disused finger

Waste castings found in the foundry or foundry; External waste refers to the waste products found after the delivery of castings, which cause much greater economic losses than internal waste.

The theory of casting forming is often called casting, and the technology of casting forming has a long history. As early as 5000 years ago, our ancestors were able to cast red copper and bronze products. Casting is a widely used gold

It belongs to wave forming process. It is a method of pouring liquid metal into the mold cavity and obtaining a certain shape of blank or part after its solidification. -

casting

The quality inspection results of castings are generally divided into three categories: qualified products, reworked products and scrap products.

1) Qualified products refer to castings whose appearance quality and internal quality meet relevant standards or technical conditions for delivery and acceptance;

2) Reworked products refer to castings whose appearance quality and internal quality do not fully meet the standards and acceptance conditions, but are allowed to be repaired, and can meet the requirements of the standards and technical conditions for delivery and acceptance of castings after repair;

3) Waste products refer to castings that are unqualified in appearance and internal quality, and are not allowed to be repaired or still fail to meet the requirements of standards and technical conditions for delivery and acceptance after repair. Waste products are divided into internal waste and external waste. Internal disused finger

Waste castings found in the foundry or foundry; External waste refers to the waste products found after the delivery of castings, which cause much greater economic losses than internal waste.

The theory of casting forming is often called casting, and the technology of casting forming has a long history. As early as 5000 years ago, our ancestors were able to cast red copper and bronze products. Casting is a widely used gold

It belongs to wave forming process. It is a method of pouring liquid metal into the mold cavity and obtaining a certain shape of blank or part after its solidification. -

Casting

The quality inspection results of castings are generally divided into three categories: qualified products, reworked products and scrap products.

1) Qualified products refer to castings whose appearance quality and internal quality meet relevant standards or technical conditions for delivery and acceptance;

2) Reworked products refer to castings whose appearance quality and internal quality do not fully meet the standards and acceptance conditions, but are allowed to be repaired, and can meet the requirements of the standards and technical conditions for delivery and acceptance of castings after repair;

3) Waste products refer to castings that are unqualified in appearance and internal quality, and are not allowed to be repaired or still fail to meet the requirements of standards and technical conditions for delivery and acceptance after repair. Waste products are divided into internal waste and external waste. Internal disused finger

Waste castings found in the foundry or foundry; External waste refers to the waste products found after the delivery of castings, which cause much greater economic losses than internal waste.

The theory of casting forming is often called casting, and the technology of casting forming has a long history. As early as 5000 years ago, our ancestors were able to cast red copper and bronze products. Casting is a widely used gold

It belongs to wave forming process. It is a method of pouring liquid metal into the mold cavity and obtaining a certain shape of blank or part after its solidification. -

Casting

The quality inspection results of castings are generally divided into three categories: qualified products, reworked products and scrap products.

1) Qualified products refer to castings whose appearance quality and internal quality meet relevant standards or technical conditions for delivery and acceptance;

2) Reworked products refer to castings whose appearance quality and internal quality do not fully meet the standards and acceptance conditions, but are allowed to be repaired, and can meet the requirements of the standards and technical conditions for delivery and acceptance of castings after repair;

3) Waste products refer to castings that are unqualified in appearance and internal quality, and are not allowed to be repaired or still fail to meet the requirements of standards and technical conditions for delivery and acceptance after repair. Waste products are divided into internal waste and external waste. Internal disused finger

Waste castings found in the foundry or foundry; External waste refers to the waste products found after the delivery of castings, which cause much greater economic losses than internal waste.

The theory of casting forming is often called casting, and the technology of casting forming has a long history. As early as 5000 years ago, our ancestors were able to cast red copper and bronze products. Casting is a widely used gold

It belongs to wave forming process. It is a method of pouring liquid metal into the mold cavity and obtaining a certain shape of blank or part after its solidification. -

Casting

The quality inspection results of castings are generally divided into three categories: qualified products, reworked products and scrap products.

1) Qualified products refer to castings whose appearance quality and internal quality meet relevant standards or technical conditions for delivery and acceptance;

2) Reworked products refer to castings whose appearance quality and internal quality do not fully meet the standards and acceptance conditions, but are allowed to be repaired, and can meet the requirements of the standards and technical conditions for delivery and acceptance of castings after repair;

3) Waste products refer to castings that are unqualified in appearance and internal quality, and are not allowed to be repaired or still fail to meet the requirements of standards and technical conditions for delivery and acceptance after repair. Waste products are divided into internal waste and external waste. Internal disused finger

Waste castings found in the foundry or foundry; External waste refers to the waste products found after the delivery of castings, which cause much greater economic losses than internal waste.

The theory of casting forming is often called casting, and the technology of casting forming has a long history. As early as 5000 years ago, our ancestors were able to cast red copper and bronze products. Casting is a widely used gold

It belongs to wave forming process. It is a method of pouring liquid metal into the mold cavity and obtaining a certain shape of blank or part after its solidification. -

casting

The quality inspection results of castings are generally divided into three categories: qualified products, reworked products and scrap products.

1) Qualified products refer to castings whose appearance quality and internal quality meet relevant standards or technical conditions for delivery and acceptance;

2) Reworked products refer to castings whose appearance quality and internal quality do not fully meet the standards and acceptance conditions, but are allowed to be repaired, and can meet the requirements of the standards and technical conditions for delivery and acceptance of castings after repair;

3) Waste products refer to castings that are unqualified in appearance and internal quality, and are not allowed to be repaired or still fail to meet the requirements of standards and technical conditions for delivery and acceptance after repair. Waste products are divided into internal waste and external waste. Internal disused finger

Waste castings found in the foundry or foundry; External waste refers to the waste products found after the delivery of castings, which cause much greater economic losses than internal waste.

The theory of casting forming is often called casting, and the technology of casting forming has a long history. As early as 5000 years ago, our ancestors were able to cast red copper and bronze products. Casting is a widely used gold

It belongs to wave forming process. It is a method of pouring liquid metal into the mold cavity and obtaining a certain shape of blank or part after its solidification.