- Agriculture / Food

- Apparel / Textiles / Accessories

- Auto / Transportation

- Bags / Shoes / Accessories

- Electronics

- Electrical Equipment / Components / Telecoms

- Gifts / Sports / Toys

- Health / Beauty

- Home / Lights / Construction

- Machinery / Industrial Parts / Tools

- Metallurgy / Chemicals / Rubber / Plastics

- Packaging / Advertising / Office

High Temperature Industrial TV

-

Integrated High Temperature Industrial TV

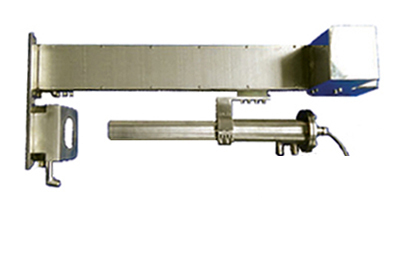

Integrated high temperature industrial TV gathered retraction system and camera & lens probe together, which is quite different from traditional separated one.

For the small camera is put inside the rod of cylinder,it is obliviously this structure is more portable, and requires less installation space.

The whole system is quite suitable to vacuum oven and positive-pressure furnace, which with a highly requirement of leakproofness. -

2-Cylinder High Temperature Industrial TV

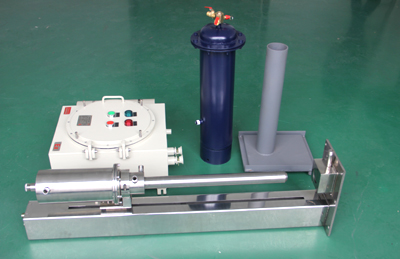

2-Cylinder high temperature industrial TV is especially designed for blast furnace.

As we know the traditional blast furnace camera systems are all manual, operators should put probe out of furnace by hands, it will not only require lots of labour force, but also exist a big security risk, for the coal gas of furnace inside.

And for the system, if the temperature is over, it only alarm but can not withdraw. Our system will solve these two problems, the detector will receive signal when over-temperature or over-pressure,then the auto-retraction system works whole system will withdraw automatically. -

Endoscopic High Temperature Industrial TV

Including SG-FV450/550/650/750/850/1100/3000/4000.

Our high-temperature CCTV camera monitoring systems provide plant engineers and operators in the control room with views of burner flames, material alignment and movement, and other process conditions in furnace, kiln, heating stove or other combustion chamber.

We use special CCD color camera above 480 lines, elbow viewing pinhole lens and the stainless steel camera housing with water or air cooling system, enabling the system working in the environment up to 2000°C.

SG-FV series can be inserted 400mm-4000mm into the furnace.

The system has auto-retraction function. The camera will exit out of the furnace, when the temperature in the inner of camera housing is higher than the setting value or the pressure of compressed air lower than the setting value or the power failures.

Application in Glass furnace, Cement kiln, Metal reheat furnace, Power furnace,etc. -

Wall Type High Temperature Industrial TV

Wall type high temperature industrial TV means the system should be fixed on the furnace wall. In a normal working state, its probe will put maximum 100mm into the wall, but not through the wall. Thus this model is quite suitable to the wall with less thickness and the target object should be very close to the observation hole.We suggest uses to make the observation hole like a bell-mouth.

Our camera system with auto retraction system so that the probe can withdraw under some emergencies,like water/air supply cut off or power outage. We also provide another simple manual mode l, semi-fixed high temperature camera system,without auto-retraction system only mechanical drive, will send alarm signal when overtemperature or undervoltage. -

Blast Furnace Top High Temperature Industrial TV

Including SG-SX503 & SG-SX508.

The blast furnace infrared camera imaging system is a kind of special infrared camera system with ball valve sealing, which could be used on furnace top in iron works.

It is cooled by water and air. It uses water cooling device at the outside of probe. At the head of the inside layer, it carries through the forced cooling to the camera and lens by compressed Nitrogen. The air spurts out and forms an air curtain in the front of puncture. In this way, it can efficiently prevent lens from being eroding by high temperature and powder infurnace.

The camera lens is fixed into the kiln wall. Through the hole in the wall, you can directly observe the charging, surface, burning and temperature of material. This technology not only ensures the safety of manufacturing, improves the working environment, reduces the working strength but also be convenient for centralized direction and automation in working process. -

Blast Furnace Tuyere High Temperature Industrial TV

Blast furnace tuyere high temperature industrial TV can timely detect coal injection, tuyere damage of abnormal furnace condition, observe the bright degree of tuyere 24 hours online , coal haulage;

Understand the uniformity of circumferential direction of blast furnace and thermal condition of the furnace hearth; Can automatically save video images and played back, facilitate production accident analysis;

At the same time completed multichannel video monitoring, can zoom any image;

Real-time analysis of tuyere coal injection situation, when pipe plugging condition occurs, the system also can automatically alarm. -

Boiler Drum Water Lever Monitor

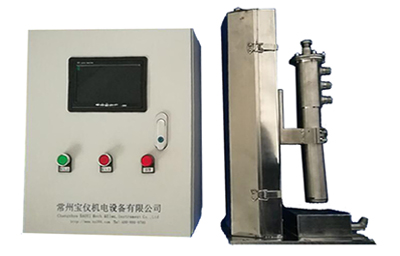

It is very important to monitor the drum water level, when the boiler works. Besides electric contact water level gauge and single room balance container to monitor the drum water lever remotely, the local water level meters are also installed on the drum two sides.

In order to observe the indication of local water level lever in control room, a boiler drum water level is necessary.

This system can display the drum dual color meter indication on the color monitor separately. In control room, you can change the zoom by remote control and select the two sides water level indications. -

Sealed High Temperature Camera System

Including ball chuck type & ball valve type.

The sealed high temperature CCTV aims at the special area for highly sealed required, toxic gas, or positive pressure in the kiln and antioxidation.

In order to be well sealed and make the maintenance convenient when using, the camera probe is connected with ball valve, also many layers of high temperature sealed material are added in.

When working in normal condition, the high temperatureens drill through the ball valve and send the imaging of the inner furnace to the video collectol system through high distinct digital camera. The special software can analyze the temperature and the physics property of the material.

The alarm function will work when the temperature of camera system rise because of under pressure or water supply cuts off.

Application in iron blast furnace, glass tin-bath, color iron plate reheat furnace nonferrous metal reheat furnace, power boiler, etc. -

Fixed High Temperature Camera System

Fixed high temperature camera system usually used in vacuum furnace, blast furnace, and annealing furnace, which from steel plant, power plant and machine plant. Probe should be put through furnace, to monitor the burner flames, the wear condition of kiln lining, the material alignment and movement,melting, and sintering condition.

This camera system is made of stainless steel, with good resistance to corrosion. The camera housing is specially designed for pinhole lens, with pinhole sharp front cover, the cooling compressed air will form a air curtain to cooling the front. And the inner layer, compressed air will go through it to cool camera and lens directly, at last out of the front cover, thus will protect the whole probe from heat, dust and even slag.