- Agriculture / Food

- Apparel / Textiles / Accessories

- Auto / Transportation

- Bags / Shoes / Accessories

- Electronics

- Electrical Equipment / Components / Telecoms

- Gifts / Sports / Toys

- Health / Beauty

- Home / Lights / Construction

- Machinery / Industrial Parts / Tools

- Metallurgy / Chemicals / Rubber / Plastics

- Packaging / Advertising / Office

Mixing Equipment

-

FS series square vibrating screen

Overview

The machine is composed of three major parts: the screen box at the inlet and outlet, the vibration source and the shock absorber. There are 4-6 sets of soft rubber shock absorbers connected to the machine base and the screen box to fix them up and down. Centrifugal force is generated when the machine is turned on. The amplitude is controlled by the eccentric block and the shock absorbers correspondingly, so as to achieve the required working performance and make the material have a throwing vibration and loosening. the sieving process. It is widely used as an ideal equipment for screening in pharmaceutical, food, chemical, metallurgical, electronic and other industries. -

JRF series coal-fired hot air stove

Working principle

The furnace integrates combustion and heat exchange with the latest indirect heating technology for heat exchange at high temperature parts of the furnace body. Smoke and air go their own way, heating is absolutely pollution-free, with high thermal efficiency (up to 60-75%) and fast heating. Small size, easy installation, reliable use, and low price (compared with a one-ton boiler, the heating system is only half the price of the boiler heating system).

Performance characteristics

High temperature resistance measures are adopted, so that its service life is greatly extended compared with the tube-type hot blast stove, and the flue gas longitudinally flushes the heat sink and the negative pressure smoke exhaust method, the heat exchange part does not accumulate dust, no cleaning is required, and the thermal performance is excellent. Stablize. All kinds of coal or firewood can be used as fuel, and it is equipped with a secondary air intake device for complete combustion. The technical and economic indicators of the furnace have reached the domestic leading level.

Applicable materials

The furnace is a general-purpose hot air device, which is used in conjunction with drying equipment for various materials. Widely used in heating and dehumidification of agricultural products, food, pharmaceuticals, chemical raw materials, light and heavy industrial products, such as grain, seeds, feed, fruit, dehydrated vegetables, fragrant rutabagas, fungus, tremella, tea, tobacco leaves, etc., and can also be used for heating and dehumidification of various facilities And warehouse dehumidification, etc. -

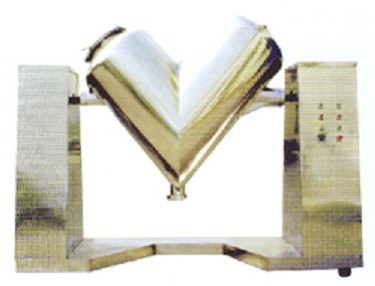

V-type mixer

This machine is suitable for mixing more than two kinds of dry powder and granular materials in pharmaceutical, chemical, food and other industries. The mixing cylinder of the machine has a unique structure, high mixing efficiency, no dead corners, is made of stainless steel, the inner and outer walls are polished, the appearance is beautiful, the mixing is uniform, and the applicable surface is wide. It can also be equipped with a forced mixer according to the user's requirements, so as to adapt to the mixing of fine powder particles, blocks, and materials containing a certain amount of water.

-

Trough type mixer

The trough mixer is used to mix powdery or wet materials, so that the main and auxiliary materials of different proportions can be mixed evenly. The contact between the machine and the material is made of stainless steel. The clearance between the blade and the barrel is small, and there is no dead angle in the mixing. There are sealing devices at both ends of the mixing shaft, which can prevent the material from flowing out. The hopper is controlled by button inching, which is convenient for discharging. It is widely used in pharmaceutical, chemical, food and other industries.

-

2D mixer

Two-dimensional motion mixer is mainly composed of barrel, upper frame (swing bed), lower frame, rotation mechanism, swing mechanism and electrical device. The two-dimensional mixer has the advantages of simple structure, low failure rate, stable operation, safe operation and no noise.

Two-dimensional motion mixer is a kind of mixer that will be used in many factories at present. If you want to use it better, you need to understand its operation process. And the operation procedures of two-dimensional motion mixer are mainly pre-operation inspection, no-load test operation, feeding, timing, mixing, unloading and cleaning equipment.

Two dimensional mixer is in two dimensions x and y axes direction movement, in the process of using, the widespread application of two dimensional mixer, first used in chemical, food and feed and various aspects of agriculture, especially some large tonnage of various mixture of solid materials, relatively will have better effect and meaning, so you can bring more convenience to various industries. -

Spiral ribbon mixer

The screw belt mixer widely used in putty paste, stone paint, dry powder, putty, medicine, food, chemicals, feed, ceramics, refractories and other solid, solid slurry mixing, especially suitable for thick material mixing. The mixer is not suitable for mixing materials with large fiber content and density difference. Putty paste, lacquer, biological, medical, food and other professions, stainless steel material is recommended. In general, mixing dry mortar material containing vitrified beads is recommended for horizontal screw belt mixer.

-

SYH multi-directional motion mixer

Purpose overview

▲The material has no centrifugal force, no gravity segregation and stratification, accumulation phenomenon, and the mixing rate can reach 99.9%.

▲The filling rate is large, up to 80% (ordinary mixer is only 40%), with high efficiency and short mixing time.

▲Every part of the barrel is arc transition, after precision polishing, it meets the requirements of "GMP". -

EYH type two-dimensional motion mixer

Purpose overview

▲This machine is widely used in pharmaceutical, chemical, food, dye, feed, fertilizer, pesticide and other industries, especially suitable for mixing various solid phase materials with large tonnage (1000~10000L).

▲The mixing cylinder of this machine participates in the swing while driving, so that the materials in the cylinder can be fully mixed. The discharge section of the mixing cylinder is equipped with spiral blades, so that the machine has the characteristics of rapid mixing, large mixing volume, and convenient discharge. -

CH tank mixer

Purpose overview

▲This machine rotates the mixing paddle through mechanical transmission, pushes the material to turn back and forth, mixes evenly, and adds adhesive at the same time to make a wet material suitable for the next process.

▲CHL high-speed mixing granulator can also be used for wet materials -

DSH series double helix conical mixer

Product Description

▲This machine is a new type, high-efficiency, high-precision mixing equipment, widely used in the mixing of various powder materials in pharmaceutical, chemical, feed and other industries.

▲The rotation of the machine is completed by a set of motor and cycloidal pinwheel reducer. It adopts two-screw asymmetrical mixing, so that the material mixing range is large, the mixing speed is fast, and the specific gravity is very different. It is more suitable for mixing relatively large materials. . The material contact parts of this machine are made of stainless steel.