- Agriculture / Food

- Apparel / Textiles / Accessories

- Auto / Transportation

- Bags / Shoes / Accessories

- Electronics

- Electrical Equipment / Components / Telecoms

- Gifts / Sports / Toys

- Health / Beauty

- Home / Lights / Construction

- Machinery / Industrial Parts / Tools

- Metallurgy / Chemicals / Rubber / Plastics

- Packaging / Advertising / Office

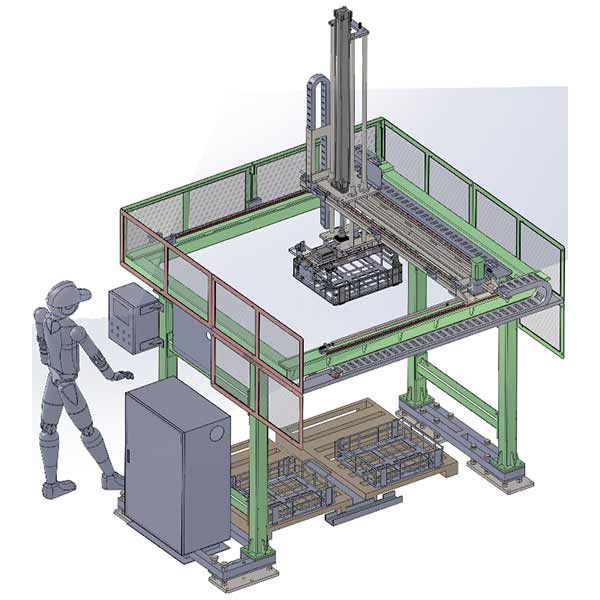

Truss Type

-

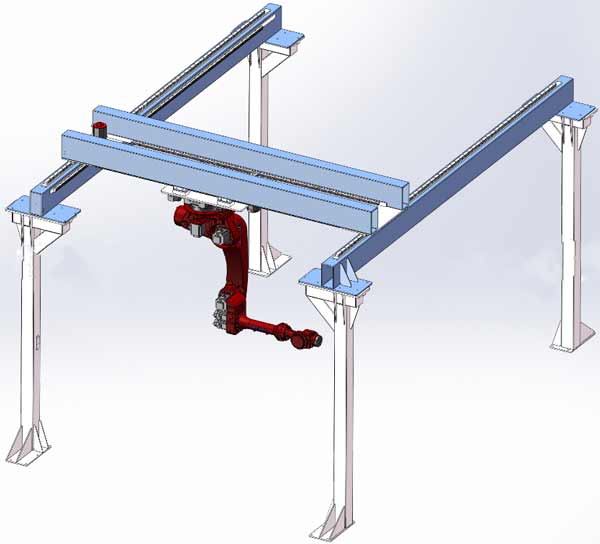

robot upside down installation truss

Truss manipulator is a kind of fully automatic industrial equipment based on the right angle X, Y, Z three-coordinate system to adjust the workpiece, or realize the trajectory movement of the workpiece. Its control core is realized through industrial controllers (such as: PLC, motion control, single-chip microcomputer, etc.). After making a certain logical judgment through the analysis and processing of various input (various sensors, buttons, etc.) signals by the controller, the execution command of each output component (relay, motor driver, indicator light, etc.) is issued to complete the joint movement between the X, Y, and Z axes, so as to realize a complete set of fully automatic operation process.

-

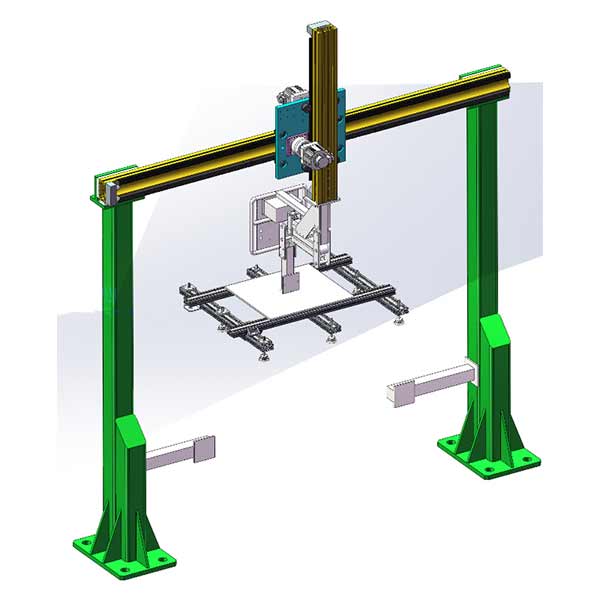

Truss with suction cups

Truss manipulator is a kind of fully automatic industrial equipment based on the right angle X, Y, Z three-coordinate system to adjust the workpiece, or realize the trajectory movement of the workpiece. Its control core is realized through industrial controllers (such as: PLC, motion control, single-chip microcomputer, etc.). After making a certain logical judgment through the analysis and processing of various input (various sensors, buttons, etc.) signals by the controller, the execution command of each output component (relay, motor driver, indicator light, etc.) is issued to complete the joint movement between the X, Y, and Z axes, so as to realize a complete set of fully automatic operation process.

-

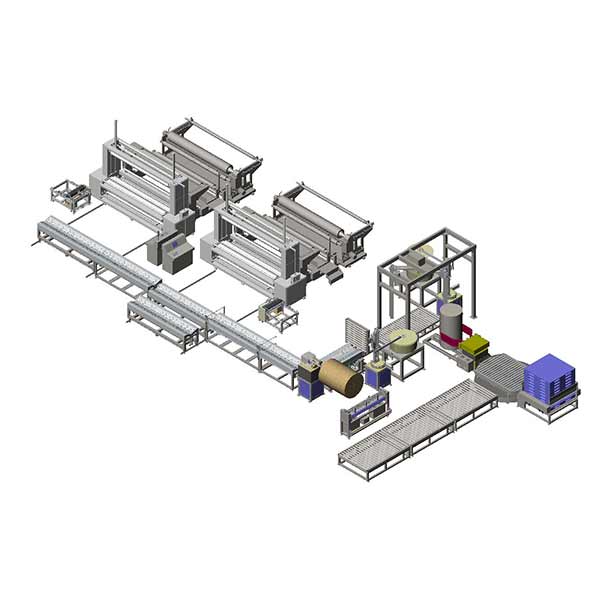

Trusses are used to transfer products

Truss manipulator is a kind of fully automatic industrial equipment based on the right angle X, Y, Z three-coordinate system to adjust the workpiece, or realize the trajectory movement of the workpiece. Its control core is realized through industrial controllers (such as: PLC, motion control, single-chip microcomputer, etc.). After making a certain logical judgment through the analysis and processing of various input (various sensors, buttons, etc.) signals by the controller, the execution command of each output component (relay, motor driver, indicator light, etc.) is issued to complete the joint movement between the X, Y, and Z axes, so as to realize a complete set of fully automatic operation process.

-

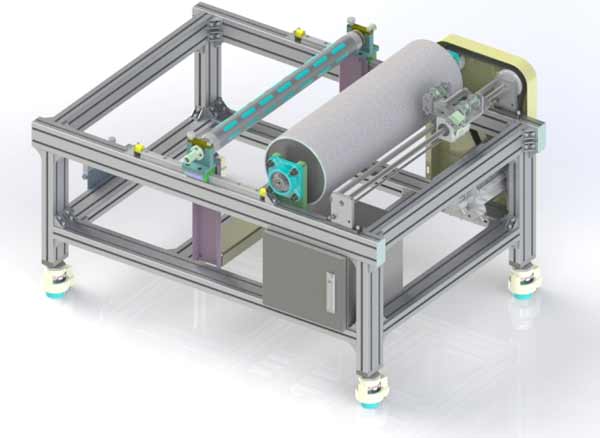

Edge Takeover

This equipment can now well solve the current situation of manual recycling of offcuts in the non-woven slitting industry, and is also suitable for non-woven slitting and closing places. In addition to manually loading the cutting edge material on the machine and manually unloading after winding the edge material, this machine is an intelligent operation, which greatly reduces the manual labor intensity and improves the safety of the work.

2) The machine is oriented development and design, which can change the corresponding parameters at any time according to the actual slitting work needs to meet the needs of slitting and recycling offcuts.

3) The equipment is small in size, does not occupy space, is easy to move, can be competent for a variety of occasions, and the later maintenance is simple, the work is reliable, and a new type of tightness adjustment device for recycling of the scrap is installed, so that the recycled offcuts are elasticated and appropriately wound on the paper cylinder, which is convenient for the transportation and processing of the later recycling, which greatly facilitates the customer's later work.

4) Main function: Linked with the non-woven slitting machine, the two scraps of the slitting machine are automatically wound and recycled synchronously, and the offcuts can be controlled to 2-3cm.