- Agriculture / Food

- Apparel / Textiles / Accessories

- Auto / Transportation

- Bags / Shoes / Accessories

- Electronics

- Electrical Equipment / Components / Telecoms

- Gifts / Sports / Toys

- Health / Beauty

- Home / Lights / Construction

- Machinery / Industrial Parts / Tools

- Metallurgy / Chemicals / Rubber / Plastics

- Packaging / Advertising / Office

Crusher

-

Universal Crusher

This machine adopts a wind wheel type high-speed rotary knife, and the fixed knife is used for impact, shearing and grinding. Not only is the crushing effect good, but also a strong air flow is generated in the cavity at the time of crushing, which flows out the heat of the crushing chamber and the finished product from the screen mesh. The crushing fineness can be determined by replacing the screen mesh.

-

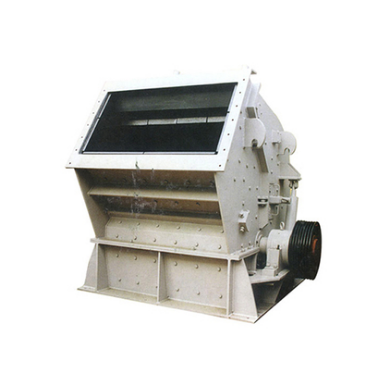

Crusher

This product has been widely used in recent years, and can be widely used in cement plants, power plants and other departments. It is not only used to crush coal, brick, limestone and other materials, but also used to crush fiber structures, such as asbestos cement. The utility model has the advantages of large crushing ratio, uniform discharging particle size, less over crushed materials, high crushing efficiency, low energy consumption, etc. It is suitable for crushing limestone, shale, coal, gypsum and other brittle materials below medium hardness.

-

Micropulverizer

It is composed of main engine, auxiliary engine and electric control. It is compact in design and reasonable in structure. It is of air separation type without screen or mesh The machine is equipped with a grading structure, which can enable crushing and grading to be completed at one time. Negative pressure conveying can continuously discharge the heat energy source generated in the cavity during crushing operation, so it is also suitable for crushing heat sensitive materials. This machine is suitable for wide range, continuous production process, and adjustable discharge particle size; Capable of crushing and grad- ing various materials such as chemicals, food, drugs, cosmetics, dyes, resins, shells, etc.

-

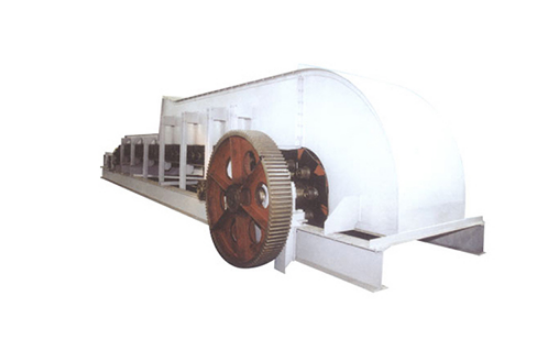

Plate feeder

Heavy plate feeder is a conveying equipment that can convey materials of different sizes and bulk weights to various receiving devices. It is mainly used for continuous and uniform transfer from the storage bin to the crusher, conveyor or other machinery

Feeding can also be used for short-distance transportation of materials with large size and density, and is widely used in mining, metallurgy, building materials, chemical, coal and other industries.

The equipment is divided into two types: horizontal installation and inclined installation, with a large inclination up to 25 °. Variable frequency motor speed regulation and hydraulic motor speed regulation can be controlled and interlocked with the material receiving device to ensure that the material receiving device reaches its maximum

Efficiency. -

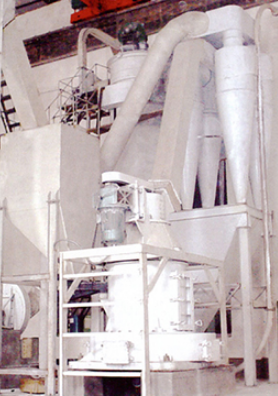

Superfine pendulum mill

The pendulum superfine grinding machine includes the mainframe, which is equipped with the mainframe motor.

The main frame is equipped with a grinding ring seat, which is installed on the inside of the grinding ring seat. The grinding ring seat is equipped with a transmission assembly, which is connected with the main motor. The transmission assembly is equipped with a quincunx frame, which is equipped with at least three hanging roller assemblies. Each hanging roller assembly is connected with a clearance adjustment device. The grinding ring seat is also equipped with an air inlet device, which is located on the upper part of the grinding ring. A cover cylinder is installed above the grinding ring seat, and a blade is installed on the transmission assembly. The transmission assembly of this swing ultra-fine mill drives the plum blossom frame to rotate under the drive of the motor, so that the grinding pressure between the grinding roller and the grinding ring is always large enough to adapt to a variety of raw materials. Due to the clearance adjustment device, there is a clearance of 0.01-3 mm between the grinding roller and the grinding ring, which can make the mill free from vibration and noise during operation. It can also reduce the contact between materials and rolled parts and improve the product quality. -

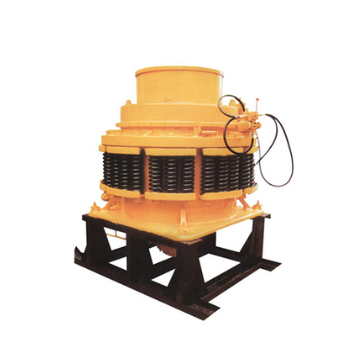

Multi-cylinder hydraulic cone crusher

The multi cylinder hydraulic cone crusher is a combination of advanced crushing technology of Red Star Machine and structural and technical upgrading and transformation on the basis of traditional spring cone crusher. It can be used in mining, metallurgy, construction, chemical industry, power, highway and other industries to process stones. At present, it is a typical representative of hard stone crushing and fine crushing operations. The machine has advanced technology, good performance and stability, and is popular with users.

Multi-cylinder hydraulic cone crusher is an advanced crushing equipment, which can be used to process quartz stone, limestone, copper ore, river pebble, bluestone, granite and other crushing operations, and is often used in infrastructure construction such as roads, railways, bridges, airports, buildings and so on.

working principle

When the multi-cylinder hydraulic cone crusher is working, it will swing along the inner surface, squeeze and bend the material close to the moving cone to achieve the effect of crushing. The broken material will fall from the cone under the action of gravity, and continuously rotate and crush. The locking protection cylinder is used to protect and clean the crushing chamber through iron. Two hydraulic cylinders are equipped with a slow-middle accumulator. During the crushing process, a small number of hard materials will be prevented from causing the jumping impact of the adjusting ring. -

Jaw crusher

This series of products has the characteristics of large crushing ratio, uniform product size, simple structure, reliable work, simple maintenance, and economic operating costs. It is widely used in mining, smelting, building materials, highway, railway, water conservancy, chemical industry and many other sectors, breaking various materials with compressive strength not exceeding 320 MPa.

-

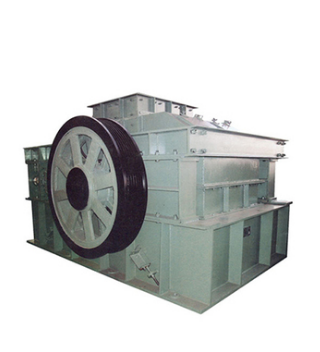

Double roll crusher

Double-roll crusher is a mechanical equipment that uses two sets of separately driven roller shafts to crush materials by relative rotation of the rolling force and grinding shear force.

When the material enters the crushing chamber of the machine, the material is forced to pass between the two rollers by the meshing force of the rotating roller shaft, and at the same time is squeezed and sheared by the roller shaft. The material starts to break, and the broken small particles

The particles are thrown under the machine through the gap between the two roller shafts along the tangent line of the roller rotation, and the large particles that exceed the gap will continue to be broken into small particles and discharged.

Double-roll crusher can be used for fine crushing of ores, rocks and refractory materials with high and medium hardness in mineral processing, chemical industry, cement, refractory materials, abrasive, construction materials and other industrial sectors. Double-roll crusher, especially in

Refractory materials and mining industry have better effects than general crushing machinery. In recent years, it is also widely used in crushing steel sand and other industries. -

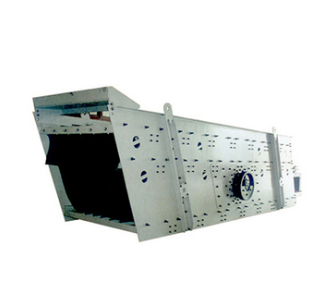

Circular vibrating screen

Principal Features

● The circular vibrating screen has novel structure, advanced technical parameters, large processing capacity and high screening efficiency.

● The circular vibrating screen uses the vibrating motor as the vibration source, which is convenient for use and maintenance.

● The round vibrating screen adopts spring steel woven screen or medium-hole screen plate, which has long service life and is not easy to block holes.

● The circular vibrating screen adopts rubber vibration isolation spring, which has long service life, low noise and stable resonance area.

Use and maintenance of circular vibrating screen

The vibrating screen should be started when there is no material on the screen surface. Try to avoid starting with material. The material can be mixed only after the screen machine runs smoothly. Stop feeding before shutdown, and stop the machine after the surface materials are removed. You should

Regularly observe the operation of the screen machine. If abnormal movement or abnormal noise is found, stop the machine for inspection in time to find out the cause and eliminate the fault. -

Cone crusher

This series of crusher is suitable for crushing various ores and rocks with medium or higher hardness. It is characterized by reliable structure, high production efficiency, convenient adjustment and economic use. Its spring safety system is an overload protection device, which can use foreign iron blocks to pass through the crushing chamber without harming the machinery. It adopts dry oil or water sealing forms to isolate the stone powder from the lubricating oil and ensure reliable operation. The type of crushing chamber is determined by the use of ore, and the standard type is suitable for medium crushing; Medium size suitable for fine crushing; Short head type is suitable for fine crushing.

-

Universal crusher (30B, 40B)

The universal high-efficiency pulverizer unit consists of a pulverizer, an ESC material collection box and an ESC dust collector. Solve the problem of dust flying during material crushing. The working principle of this machine is that the material enters the crushing chamber and is crushed under the impact, shearing, friction and mutual impact of the teeth between the high-speed rotating movable tooth plate and the fixed tooth plate. After screening, it becomes the required powder.