- Agriculture / Food

- Apparel / Textiles / Accessories

- Auto / Transportation

- Bags / Shoes / Accessories

- Electronics

- Electrical Equipment / Components / Telecoms

- Gifts / Sports / Toys

- Health / Beauty

- Home / Lights / Construction

- Machinery / Industrial Parts / Tools

- Metallurgy / Chemicals / Rubber / Plastics

- Packaging / Advertising / Office

Welding Equipment

-

Welding manipulator

Effective stroke of vertical boom from 800mm to 8000mm, 2000mm to 8000mm,

also can be customized as per tank diameter.

A smooth +1 80°degree rotation.

Pendant with 6m cable .

A standard safety include , anti-fall device and limit switches for all motions .

Movable carriage or fixed stand. -

Conventional rotator

Conventional roller beds are a basic solution for the handling of a variety of

workpieces, such as welding ,polishing ,glue-lining,and assenmling of the cylinder

body.

Conventional rotator standard size is from 2T to 500T, beyond this range please

contact us for further communication.

The adjustment of roller distance according to diameter is carried out by manual.

Rotation is even and certain, the whole welding process can be effectively

automated. -

Self-adjustable welding rotator

Compared with the conventional type , The roller-bogie align itself automatically with

the diameter of the work-piece.

This series welding rotator enables a more even weight distribution, a significant

advantage when welding thin-walled work-piecelvessels .

The whole welding process can be effectively automated. -

Hydraulic fit up welding rotator

Application for joining of long pipe such as wind tower.

High efficiency for 1+1 can assembly process.

One set consist of one power and one idler roller bed, four independently adjusted

rollers to align the tWo cans with each other.

It is used together with standard conventional powered and idler rotator. -

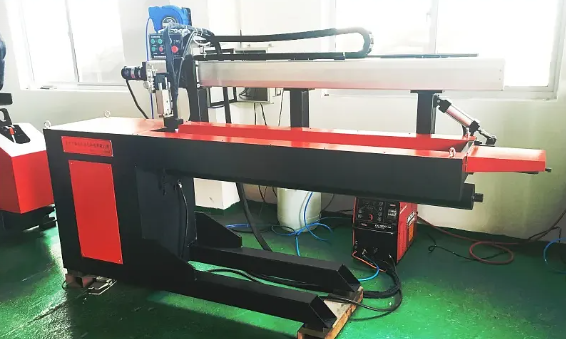

Straight seam welding equipment

Equipment Overview:

Introduction: All weldable materials can be welded on this longitudinal seam automatic welding machine, such as stainless steel, carbon steel, weldable aluminum alloy, heat-resistant alloy, zirconium alloy, alloy and other materials. The workpiece structures that can be clamped and welded include metal sheets, round and simple workpieces, conical cylinders, truncated cones, and box-shaped structures with one end sealed, flat plate joints, etc. Optional gas shielded welding/MAG, TIG welding, P+T double gun welding Equipment features: integrated structure, piano-key type clamping structure, optional pneumatic and infrared alignment, replaceable mandrel support structure, suitable for a wide range of weldable materials, back protection gas and water cooling, single-sided welding and double-sided forming, ZF series optional heightened seat, suitable for large diameter workpieces. -

Rotating gun welding equipment

Equipment Overview:

Mainly used for pipe-to-pipe saddle welding of hydraulic cylinder nozzles, container pipe seats and other T-shaped positions. The equipment mainly includes a frame, a lifting platform, a rotating shaft, a wire feeding system, a TG (gas shielded welding) welding gun, a welding gun bracket, a saddle-shaped tracking bracket, a PLC control system, etc.

Equipment Features:

Integrated, self-positioning, mechanical tracking of welds, and a lifting and lowering tooling platform.